Tin bronze precision castings for engine parts provide unparalleled durability and efficiency. These tin bronze precision castings, crafted from a copper and tin alloy, are recognized for their outstanding strength and resistance to corrosion. With a tensile strength ranging from 450 to 780 MPa, they can withstand heavy loads without deforming. The low shrinkage during the casting process guarantees precise dimensions, while additives such as phosphorus improve hardness and wear resistance. These characteristics make tin bronze silica sol precision casting parts particularly suitable for components like bearings and bushings, which endure constant wear and tear.

Key Takeaways

- Tin bronze castings make engines last longer and work better. They are great for tough parts like bearings and bushings.

- This alloy resists rust and wear, so it needs less fixing. This saves engine owners both time and money.

- Using tin bronze instead of steel or aluminum makes parts stronger and lighter. This helps engines work well in tough conditions.

Tin Bronze Precision Castings for Engine Parts: Composition and Properties

What is Tin Bronze? Key Composition and Characteristics

Tin bronze is a copper-based alloy that contains tin as its primary alloying element. This material is widely recognized for its exceptional mechanical properties and versatility. Depending on the application, manufacturers may adjust the composition to achieve specific characteristics. For example, standard tin bronze typically contains 88-90% copper and 10-12% tin, offering enhanced strength and wear resistance. Low-tin bronze, with 5-7% tin, provides increased ductility, making it ideal for intricate designs. High-tin bronze, on the other hand, is harder and more wear-resistant, making it suitable for heavy-duty applications.

| Type of Tin Bronze | Copper Content (%) | Tin Content (%) | Properties |

|---|---|---|---|

| Standard Tin Bronze | 88-90 | 10-12 | Enhanced material properties |

| Low-Tin Bronze | 88-95 | 5-7 | Increased ductility, ideal for intricate designs |

| High-Tin Bronze | 88-88 | 10-12 | Harder, more wear-resistant, suitable for heavy-duty applications |

| Additional Elements | Varies | Varies | Improves specific properties (e.g., strength, corrosion resistance) |

The addition of other elements, such as phosphorus or iron, further enhances the alloy’s performance. Phosphorus increases hardness and wear resistance, while iron improves grain refinement and processing performance. These characteristics make tin bronze precision castings for engine parts a reliable choice for high-stress environments.

Key Points:

- Tin bronze is a versatile alloy with adjustable compositions for specific applications.

- Standard, low-tin, and high-tin bronze offer unique properties like wear resistance, ductility, and hardness.

- Additives like phosphorus and iron enhance performance in demanding conditions.

Mechanical Strength and Corrosion Resistance

Tin bronze stands out for its remarkable mechanical strength and corrosion resistance, making it a preferred material for engine components. Studies show that the tensile strength of leaded-tin bronze alloys can reach up to 192 MPa, depending on the alloying elements and casting conditions. The alloy’s peak hardness increases with higher tin content and aging time, directly correlating with improved mechanical strength.

| Evidence Type | Description |

|---|---|

| Mechanical Strength | Peak hardness increases with tin content and aging, enhancing strength. |

| Corrosion Resistance | Additives improve resistance to corrosive wear in various environments. |

| Wear Rate | Decreases with increased hardness, supporting durability. |

| Effect of Additives | Sliding additives like graphite enhance wear resistance and performance. |

Corrosion resistance is another standout feature of tin bronze. The material performs exceptionally well in harsh environments, including exposure to saltwater and high temperatures. Tin enhances the alloy’s toughness and wear resistance, while additives like graphite reduce friction and improve sliding performance. These properties ensure that tin bronze precision castings for engine parts can withstand rigorous operating conditions without compromising efficiency.

Key Points:

- Tin bronze offers high tensile strength and hardness, ideal for engine components.

- Corrosion resistance ensures durability in harsh environments, including saltwater exposure.

- Additives like graphite improve wear resistance and reduce friction.

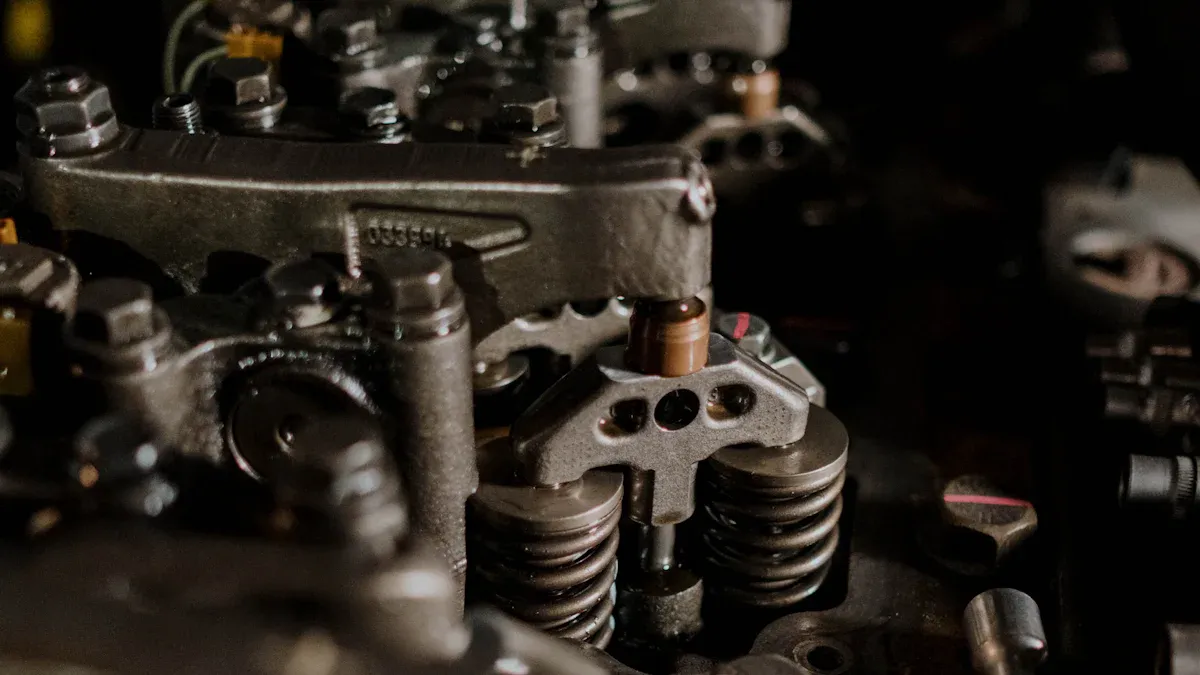

Real-World Example: Tin Bronze in High-Performance Engines

High-performance engines demand materials that can endure extreme conditions without failure. Tin bronze precision castings for engine parts excel in such applications. For instance, tin bronze is commonly used in bushings, valve parts, gears, pumps, piston rings, and bearings. These components face constant stress, friction, and heat, making durability a top priority.

- Tin increases the alloy’s elasticity and fatigue resistance, ensuring long-term performance.

- The material’s toughness and wear resistance reduce the need for frequent maintenance.

- Its ability to withstand high sliding velocities enhances efficiency in demanding operations.

Marine diesel engines provide a practical example of tin bronze’s capabilities. These engines operate in corrosive saltwater environments and require materials that can resist wear and corrosion. Tin bronze components, such as bearings and bushings, ensure smooth operation and extended engine life. By reducing friction and wear, these parts contribute to lower maintenance costs and improved fuel efficiency.

Key Points:

- Tin bronze is widely used in high-stress engine components like bushings and bearings.

- The material’s elasticity, toughness, and wear resistance ensure durability and efficiency.

- Marine diesel engines highlight tin bronze’s ability to perform in harsh environments.

Applications of Tin Bronze Precision Castings in Engine Components

Bearings: Enhancing Friction Reduction and Longevity

Bearings play a crucial role in reducing friction between moving parts in an engine. Tin bronze precision castings for engine parts are ideal for bearings due to their antifriction properties and wear resistance. These characteristics ensure smooth operation and extend the lifespan of the engine.

- Tin bronze bearings minimize wear and friction thanks to their low coefficient of friction.

- Plain bearings made from tin bronze are designed to handle mechanical stresses effectively.

- The material’s durability reduces the need for frequent replacements, saving time and costs.

By using tin bronze bearings, engines can operate more efficiently, even under high-stress conditions. This makes them a preferred choice for automotive and marine applications where reliability is critical.

Key Points:

- Tin bronze bearings reduce friction and wear, ensuring smooth engine operation.

- Their durability lowers maintenance costs and extends engine life.

Bushings: Supporting Heavy Loads in Engine Systems

Bushings are essential for supporting heavy loads and enabling smooth movement in engine systems. Tin bronze bushings excel in heavy-duty applications due to their high load capacity and exceptional wear resistance. Their design features, such as punched-through holes, enhance lubrication and reduce maintenance needs.

- Tin bronze bushings support radial, oscillating, and axial movements, making them versatile for various engine systems.

- They outperform plastic bushings in durability and load capacity, ensuring reliable performance in demanding environments.

- Their ability to handle extra-high loads makes them indispensable for heavy machinery and marine engines.

These bushings not only improve engine efficiency but also contribute to longer operational lifespans, making them a cost-effective solution for industries like automotive and engineering.

Key Points:

- Tin bronze bushings offer high load capacity and durability for heavy-duty applications.

- Enhanced lubrication reduces maintenance needs and improves efficiency.

Valve Guides: Improving Heat Resistance and Efficiency

Valve guides are critical for maintaining the alignment of engine valves and ensuring efficient combustion. Tin bronze precision castings for engine parts provide excellent heat resistance, making them ideal for valve guides in high-temperature environments.

- Tin bronze valve guides withstand extreme heat without deforming, ensuring consistent performance.

- Their wear resistance reduces friction, enhancing the efficiency of the engine.

- The material’s toughness ensures long-term reliability, even under continuous stress.

By improving heat resistance and reducing wear, tin bronze valve guides contribute to better fuel efficiency and lower emissions, aligning with modern environmental standards.

Key Points:

- Tin bronze valve guides resist high temperatures and wear, ensuring reliable engine performance.

- Their efficiency boosts fuel economy and reduces environmental impact.

Case Study: Tin Bronze Components in Marine Diesel Engines

Marine diesel engines operate in harsh environments, including exposure to saltwater and high mechanical stress. Tin bronze components, such as bearings, bushings, and valve guides, have proven their effectiveness in these conditions.

| Property | Benefit in Marine Diesel Engines |

|---|---|

| Resistance to salt-water | Reduces corrosion, enhancing the lifespan of components |

| Resistance to dezincification | Maintains structural integrity in harsh environments |

| Suitable for castings | Ideal for valves and steam fittings used in marine engines |

These properties make tin bronze precision castings for engine parts indispensable for marine applications. By resisting corrosion and maintaining structural integrity, they ensure smooth operation and reduce maintenance costs.

Key Points:

- Tin bronze components excel in marine diesel engines due to their corrosion resistance.

- Their durability and efficiency reduce operational costs and extend engine life.

Advantages of Tin Bronze Precision Castings Over Traditional Materials

Comparison with Steel: Weight and Corrosion Resistance

Tin bronze offers significant advantages over steel, especially in terms of weight and corrosion resistance. While steel is known for its strength, it is heavier and more prone to rust. Tin bronze, on the other hand, provides a lighter alternative with excellent resistance to corrosion. This makes it a better choice for applications exposed to harsh environments, such as marine engines or outdoor machinery.

| Property | Tin Bronze | Steel |

|---|---|---|

| Corrosion Resistance | Excellent resistance to corrosion, ideal for marine and outdoor applications. | Susceptible to corrosion, often requiring protective coatings. |

| Weight | Generally lighter, providing a good strength-to-weight ratio. | Heavier, suitable for structural applications where weight is a concern. |

By choosing tin bronze, manufacturers can reduce the overall weight of engine components while ensuring long-term durability in corrosive conditions.

Key Points:

- Tin bronze is lighter than steel, improving efficiency in weight-sensitive applications.

- Its superior corrosion resistance makes it ideal for harsh environments.

Comparison with Aluminum: Strength and Durability

Aluminum is often praised for its lightweight properties, but it falls short when it comes to strength and durability. Tin bronze, while slightly heavier, offers far greater mechanical strength and wear resistance. This makes it a more reliable option for engine components that experience constant stress and friction.

For example, aluminum components may deform under heavy loads or high temperatures, leading to frequent replacements. Tin bronze, however, maintains its structural integrity even in demanding conditions. Its ability to handle high-stress environments ensures a longer lifespan for critical parts like bearings and bushings.

Key Points:

- Tin bronze outperforms aluminum in strength and wear resistance.

- It provides better durability, reducing the need for frequent part replacements.

Example: Reduced Maintenance Costs in Automotive Engines

Automotive engines benefit greatly from the use of tin bronze precision castings. Components like bushings and valve guides made from tin bronze require less maintenance due to their exceptional wear resistance. This reduces downtime and lowers overall maintenance costs for vehicle owners.

Additionally, tin bronze’s ability to withstand high temperatures and friction ensures consistent performance over time. This reliability translates to fewer engine failures and improved fuel efficiency, making it a cost-effective solution for both manufacturers and consumers.

Key Points:

- Tin bronze components reduce maintenance needs, saving time and money.

- Their durability and efficiency improve engine performance and lifespan.

Tin bronze precision castings offer unmatched durability, thermal conductivity, and reduced maintenance needs, making them ideal for engine components.

| Benefit | Description |

|---|---|

| Durability | Resists wear and environmental factors, ensuring longer-lasting parts. |

| Thermal Conductivity | Prevents overheating, maintaining optimal engine performance. |

| Reduced Maintenance | Saves time and money with fewer repairs and replacements. |

To maximize these benefits, collaborate with trusted suppliers like Ningbo Pingheng Machinery Co., Ltd. Their expertise ensures the right materials for your specific needs, enhancing engine efficiency and lifespan.

FAQ

What makes tin bronze better than other materials for engine parts?

Tin bronze offers superior wear resistance, corrosion protection, and durability. These qualities make it ideal for high-stress engine components like bearings and bushings.

Can tin bronze components reduce engine maintenance costs?

Yes! Tin bronze parts last longer and resist wear, reducing the need for frequent replacements. This helps lower overall maintenance expenses for engines.

Where can I find reliable tin bronze precision castings?

Trusted suppliers like Ningbo Pingheng Machinery Co., Ltd. provide high-quality tin bronze castings. Their expertise ensures the right components for specific engine needs.

Key Points:

- Tin bronze excels in durability and wear resistance.

- It reduces maintenance costs and improves engine performance.

- Reliable suppliers ensure quality and compatibility.