Discovering the right industrial investment casting machine is key for manufacturing success. Many leading companies excel in this field. Explore their innovative Products to see how they meet diverse needs. For specific inquiries or to learn more, you can always Contact us or check their About Pingheng section for company insights.

Key Takeaways

- Choosing the right investment casting machine is important. Look for quality, good support, and new technology.

- Many factors help you pick a manufacturer. Consider their reliability, customization options, and help after you buy the machine.

- Check for industry certifications. These show the manufacturer meets high standards for quality and safety.

Top 10 Industrial Investment Casting Machine Manufacturers

Inductotherm Group: Advanced Investment Casting Machine Solutions

Inductotherm Group offers advanced solutions for investment casting. Their Consarc® VPIC furnaces ensure consistent production with minimal maintenance. These machines create near-net-shape parts, showing exceptional accuracy and surface finish. They also provide versatile configurations, fitting different space needs. Advanced process control guarantees high-quality results every time. These systems can be customized from lab-scale to high-volume production. They accommodate melt sizes from 10 lbs to 2,200 lbs.

ABP Induction Systems: Innovative Investment Casting Machine Technology

ABP Induction Systems brings innovative technology to the investment casting industry. They focus on developing cutting-edge solutions that improve efficiency and performance for foundries worldwide.

Foseco: Materials and Investment Casting Machine Expertise

Foseco provides a wide range of materials essential for investment casting. They offer exothermic powders and various filters for steel, aluminum, and copper castings. Their expertise also covers metal treatment products for both ferrous and non-ferrous alloys. You can find ladle linings, furnace linings, and different binders from them.

Remet: Binders and Investment Casting Machine Process Support

Remet stands out with its strong technical support for foundries. Their team brings over 150 years of direct foundry experience. They offer innovative solutions and quality assurance. Remet provides various binders, including their proprietary REMASOL® Colloidal Silica and enhanced binders like ADBOND® polymer. They also have traditional alcohol-based binders and specialized prehydrolyzed ethyl silicates.

Ransom & Randolph: Refractories for Investment Casting Machines

Ransom & Randolph supplies crucial refractory products for investment casting machines. Their offerings include Biovest® investment, Chromex™ Regular investment, and Neoloy® ‘E’ investment. They also provide refractory materials like Ranco-Sil™ fused silica, zircon sand, and zircon flour.

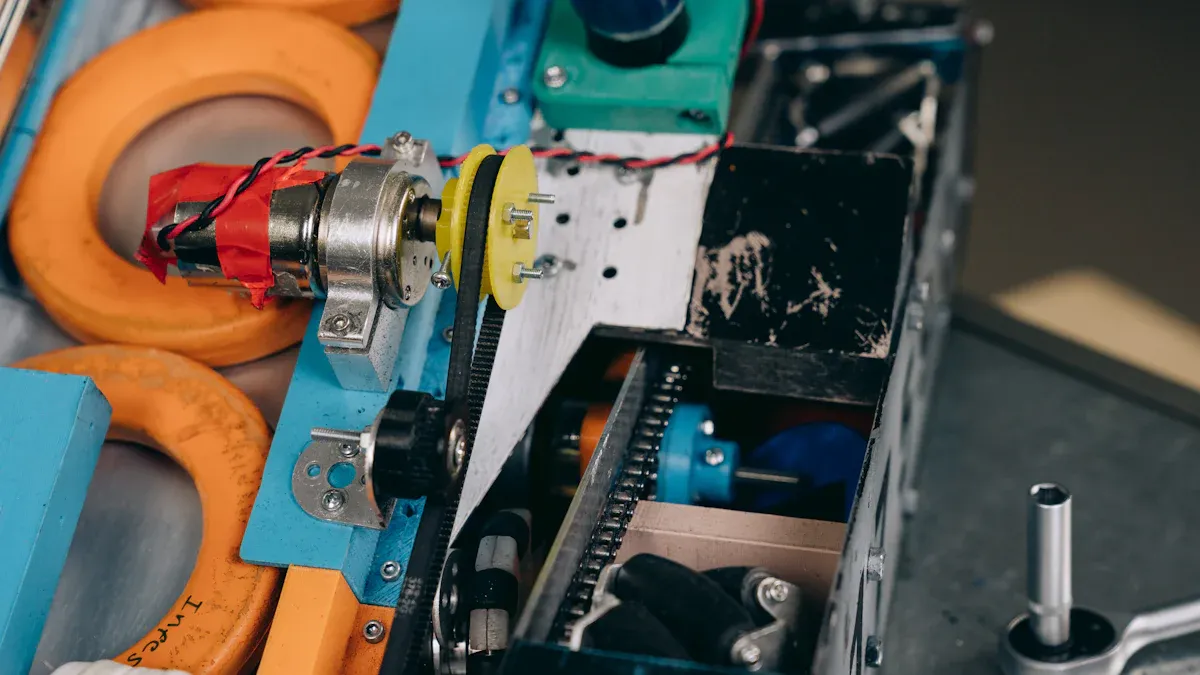

Shell-O-Matic: Automation in Investment Casting Machine Operations

Shell-O-Matic brings automation to investment casting machine operations. They use Manufacturing Execution Systems (MES) to manage all production needs. This system controls shell-making robot cells and entire factories through Industry 4.0 and IIOT. Their robust robots, in use since 1973, handle heavy loads up to 675 kg. These robots are known for their reliability and ease of maintenance.

PCC Airfoils: Precision Investment Casting Machine Applications

PCC Airfoils specializes in complex, highly technical investment castings. They produce hot section airfoils for aircraft and power generation engines. Their expertise includes directionally solidified (DS) and single crystal castings. These require very strict control of the solidification cycle. PCC Airfoils uses automated casting furnaces and advanced processes.

Alcoa Howmet: High-Performance Investment Casting Machine Components

Alcoa Howmet is a leader in high-performance components for investment casting. They focus on delivering parts that meet the demanding requirements of various industries.

Arconic: Aerospace Investment Casting Machine Capabilities

Arconic offers extensive aerospace investment casting machine capabilities. They provide advanced solutions for critical aerospace applications, ensuring precision and reliability.

Impro Precision Industries: Global Investment Casting Machine Manufacturing

Impro Precision Industries has a global presence in investment casting machine manufacturing. They offer a wide range of services and products to clients around the world.

Key Factors for Selecting an Investment Casting Machine Manufacturer

Choosing the right manufacturer for your industrial investment casting machine is a big decision. Many factors play a role in finding the best partner. Consider these key points to make an informed choice.

Quality and Reliability of Investment Casting Machines

A good investment casting machine must be built to last. Manufacturers should use high-quality materials and precise engineering. This ensures the machine works consistently and reliably. A reliable machine means less downtime and more production for your business. It also helps you produce high-quality parts every time.

Customization Capabilities for Investment Casting Machine Systems

Every foundry has unique needs. A top manufacturer offers customization options for their investment casting machine systems. They can adapt machines to fit specific production volumes, part sizes, or material types. This flexibility helps you get a system that perfectly matches your operational requirements.

After-Sales Support and Service for Investment Casting Machines

Excellent after-sales support is crucial. Look for manufacturers who offer strong technical assistance, spare parts availability, and maintenance services. Good support ensures your investment casting machine continues to run smoothly. It also helps you quickly resolve any issues that might come up.

Pricing and Value Proposition of Investment Casting Machines

The cost of an investment casting machine varies widely. You need to consider the overall value, not just the initial price. A more expensive machine might offer better features, durability, and efficiency, saving you money in the long run. Here is a general idea of price ranges for new industrial investment casting machines:

| Machine Type | Price Range (USD) |

|---|---|

| Wax Injectors | 10,000 – 50,000 |

| Ceramic Coating Systems | 20,000 – 100,000 |

| Vacuum Furnaces | 50,000 – 300,000 |

| Complete Casting Lines | 200,000 – 1,000,000+ |

Industry Certifications and Standards for Investment Casting Machines

Certifications show a manufacturer’s commitment to quality and safety. Look for companies that meet recognized industry standards. These certifications ensure the machines meet strict performance and safety guidelines.

- ISO 9001:2015: This certification focuses on quality management systems. It ensures efficient and effective processes.

- PED 2014/68/EU: This certification defines requirements for a manufacturer’s quality assurance system. It specifically covers pressure equipment.

- IATF 16949:2016: This certification is for organizations in the automotive supply chain.

- Nadcap: This accreditation is for specific processes used by aerospace suppliers, like heat treating.

- AS9100C/D: These standards are for quality management systems in aviation, space, and defense organizations.

Technological Innovation in Investment Casting Machine Design

Innovative manufacturers constantly improve their investment casting machine designs. They use new technologies to boost efficiency and accuracy. For example, simulation software like SOLIDWORKS 3D CAD and MAGMASOFT helps foundries predict casting soundness. This software improves first-time success rates. Automation also greatly enhances efficiency. Robotic systems are now common in shell-building. They ensure consistent shell thickness and allow 24/7 operation. Automated grinding and shell removal systems also reduce labor and improve quality. Furthermore, 3D printing for pattern creation significantly cuts lead times and costs. It reduces production time from weeks to days. Advancements in mold materials and coating techniques also lead to better surface finish and dimensional accuracy.

Global Reach and Local Support for Investment Casting Machines

A manufacturer with a global presence can offer broader support. They often have local service centers or partners. This means you can get help quickly, no matter where your facility is located. Local support is very important for timely maintenance and troubleshooting.

Reputation and Customer Reviews of Investment Casting Machine Providers

A manufacturer’s reputation speaks volumes. Check customer reviews and testimonials. They offer insights into a company’s reliability and service quality. Positive feedback often highlights key strengths.

- Reliability and Trustworthiness: Customers often say they can count on the manufacturer to get things done.

- Ease of Collaboration and Communication: Good manufacturers make it easy to exchange ideas and work together.

- Competence and Efficiency: Customers appreciate when a provider has the right skills to make things happen quickly.

Energy Efficiency and Sustainability of Investment Casting Machines

Modern manufacturers focus on energy-efficient designs. These machines use less power, which lowers operating costs. Sustainable practices also reduce environmental impact. Choosing an eco-friendly investment casting machine helps your business and the planet.

Training and Technical Assistance for Investment Casting Machine Operators

Proper training for operators is essential. Manufacturers should offer comprehensive training programs. These programs help your team use the machines safely and effectively. For example, some manufacturers offer certified training programs. These programs cover:

- Machine installation and start-up procedures

- Machining preparation and initial part production

- Production and process optimization

- Quality control measures

- Troubleshooting for operational issues

- Troubleshooting for maintenance issues

Making an informed decision about your industrial investment casting machine is crucial. Carefully evaluate manufacturers based on quality, support, and innovation. This strategic partnership ensures your long-term industrial success. Choose wisely to optimize your production and achieve lasting growth.

FAQ

What is investment casting?

Investment casting is a precise manufacturing process. It creates complex metal parts using a wax pattern. Workers coat the pattern in ceramic. Then, they melt out the wax. Finally, they pour molten metal into the ceramic mold. 🛠️

Why choose investment casting?

Investment casting offers high accuracy and excellent surface finish. It produces intricate shapes with minimal machining. This method is ideal for complex parts and various alloys. ✨

What materials do investment casting machines process?

Investment casting machines process many materials. These include steel, aluminum, and superalloys. They also handle titanium and other specialized metals. This versatility suits diverse industrial needs. ⚙️