Investment casting lets manufacturers create complex shapes with high accuracy.

- Brass investment casting uses copper and zinc, making it affordable with solid strength.

- Bronze investment casting relies on copper and tin, offering better corrosion resistance.

- People often choose investment precision casting based on performance needs and budget.

Key Takeaways

- Brass is easier to cast and machine, offering good strength and a shiny finish, making it ideal for decorative and indoor parts like plumbing and musical instruments.

- Bronze is stronger, harder, and more resistant to corrosion, especially in marine and harsh environments, making it the best choice for heavy-duty parts like gears, bearings, and marine hardware.

- Choosing between brass and bronze depends on the part’s use, environment, and budget; brass is more cost-effective, while bronze provides longer-lasting durability in tough conditions.

Material Composition and Properties in Investment Casting

Brass Alloy Composition and Characteristics

Brass stands out as a copper-zinc alloy, but its recipe can change a lot depending on the application. Most brass alloys for investment casting contain between 55% and 95% copper and 5% to 45% zinc. Sometimes, manufacturers add small amounts of elements like silicon, iron, aluminum, or manganese to tweak the properties. For example, silicon tombac includes about 80% copper, 16% zinc, and 4% silicon, making it a strong alternative to steel parts. Red brass (C230) has around 85% copper and 14-16% zinc, while architectural bronze (which is actually a type of brass) contains about 59% copper and 42% zinc.

Here’s a quick look at some common brass alloys used in investment casting:

| Alloy Name | Copper (%) | Zinc (%) | Lead (%) | Tin (%) | Silicon (%) | Other Elements | Notes |

|---|---|---|---|---|---|---|---|

| Silicon tombac | 80 | 16 | N/A | N/A | 4 | N/A | Alternative for steel parts |

| Red brass (C230) | ~85 | 14-16 | ≥0.07 | N/A | N/A | ≥0.05% iron | Also called copper alloy C23000 |

| Ounce metal | 85 | 5 | 5 | 5 | N/A | N/A | Sometimes called red brass |

| Alpha brasses | >65 | <35 | Small | Small | Small | Varies | Corrosion-resistant red brasses |

| Beta brasses | 50-55 | 45-50 | Small | Small | Small | Varies | Harder, stronger, suitable for casting |

Brass alloys are known for their malleability and machinability. They resist corrosion fairly well, especially in non-marine environments, and have a gold-like shine that makes them popular for decorative uses. The zinc content boosts ductility and strength, but too much zinc can lower corrosion resistance. Brass melts at around 900 °C, which helps with casting complex shapes.

Tip: Leaded brass alloys offer excellent machinability, but environmental regulations now limit their use. Many foundries prefer non-leaded brass alloys for investment casting to meet safety standards.

Bronze Alloy Composition and Characteristics

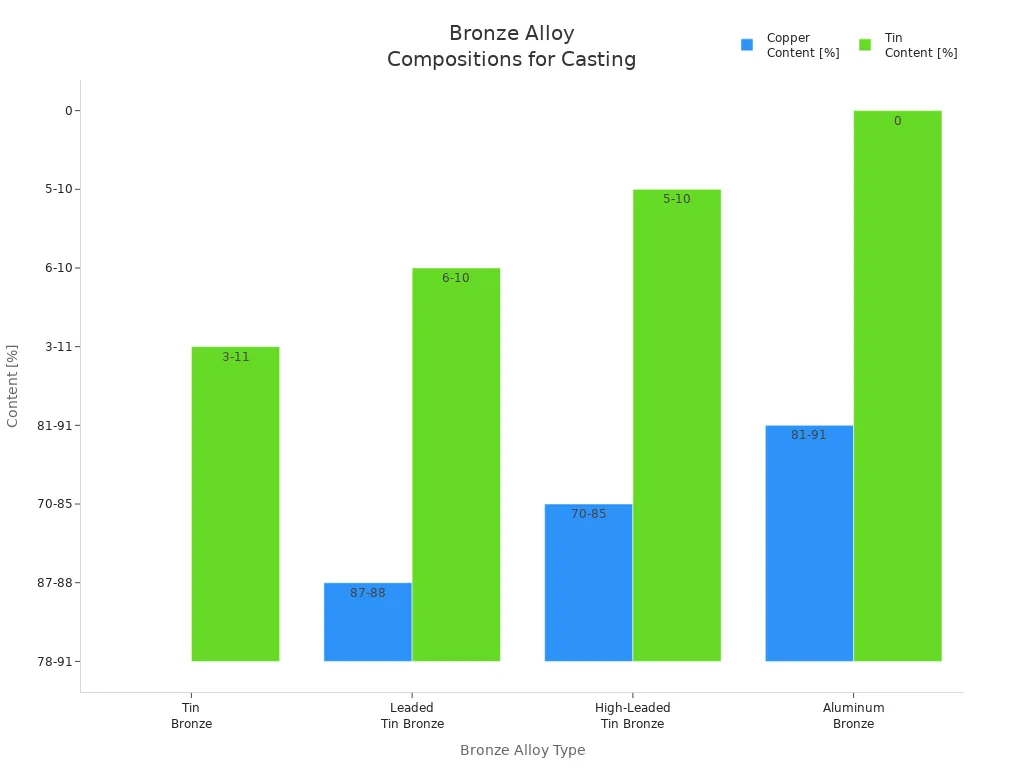

Bronze, on the other hand, is mainly a copper-tin alloy. The typical bronze used in investment casting contains about 78% to 91% copper and 3% to 11% tin. Some bronze alloys include small amounts of lead, zinc, aluminum, or phosphorus to improve specific properties. For example, aluminum bronze swaps out tin for up to 11% aluminum, which increases strength and corrosion resistance.

Here’s a table showing standard bronze alloys for investment casting:

| Bronze Alloy Type | Typical Copper Content [%] | Typical Tin Content [%] | Additional Elements (examples) |

|---|---|---|---|

| Tin Bronze | 78 – 91 | 3 – 11 | Zinc, Lead (small amounts) |

| Leaded Tin Bronze | ~87 – 88 | 6 – 10 | Lead (up to ~2%), Zinc |

| High-Leaded Tin Bronze | 70 – 85 | 5 – 10 | Lead (up to 25%), Zinc |

| Aluminum Bronze | 81 – 91 | 0 | Aluminum (up to 11%), Iron, Nickel |

Bronze alloys are harder and more brittle than brass. The tin content increases both strength and corrosion resistance, especially in saltwater. Bronze melts at a slightly higher temperature—about 950 °C. This makes it a favorite for marine hardware, bearings, and gears that need to survive tough environments.

Key Differences in Material Behavior

Brass and bronze behave differently during investment casting, and these differences matter when choosing the right alloy for a project.

- Fluidity and Shrinkage: Brass flows better in molds, with a fluidity of 40–45 cm, compared to bronze’s 30–38 cm. Brass also shrinks less (1.5% to 2.0%) than bronze (2.0% to 2.5%). This means brass is easier to cast into intricate shapes and holds tight tolerances.

- Melting Point: Bronze melts at a higher temperature (~950 °C) than brass (~900 °C). This affects the casting process and the types of molds used.

- Microstructure: Brass solidifies over a wider temperature range, which can lead to uneven grain structures if not cooled carefully. Fast cooling creates smaller grains and can increase hardness, but it also raises the risk of stress cracks. Bronze solidifies more predictably, forming dendritic structures that improve strength and reduce porosity, especially when cooled gradually.

- Mechanical Properties: Bronze is harder and more resistant to corrosion, especially in seawater. It also stands up better to wear and metal fatigue. Brass, while more ductile and easier to machine, is less suited for high-stress or highly corrosive environments.

- Environmental Considerations: Regulations now limit the use of lead in brass alloys, pushing foundries toward safer, non-leaded options. Bronze alloys, especially those with phosphorus, can reduce gas porosity and improve casting quality.

Here’s a side-by-side comparison:

| Feature | Brass | Bronze |

|---|---|---|

| Composition | Copper and Zinc; may include Iron, Aluminum, Silicon, Manganese | Copper and Tin; may include Phosphorus, Manganese, Aluminum, Silicon, Bismuth |

| Properties | More malleable, lower melting point (~900 °C), susceptible to stress cracking with ammonia | Harder, resistant to corrosion (especially seawater), metal fatigue resistant, higher melting point (~950 °C) |

| Applications | Decorative, plumbing, musical instruments | Marine fittings, bearings, gears, pumps, valves |

| Additional Notes | Zinc content affects ductility and strength; brass is more workable | Tin content increases strength and corrosion resistance; bronze is more durable and suitable for harsh environments |

Note: Investment casting allows both brass and bronze to take on complex shapes with fine details, but the choice of alloy will affect the final part’s strength, durability, and resistance to the elements.

Investment Casting Process Comparison

Brass Investment Casting Steps

Brass investment casting follows a series of precise steps to create detailed parts. Each step plays a big role in the final quality:

- Workers create wax patterns using injection molding or sculpting. This step sets the detail and accuracy for the finished part.

- They assemble the wax patterns into a tree, which helps with efficient production.

- The tree gets dipped into a ceramic slurry several times. Each layer dries before the next, building a strong mold shell.

- The wax is melted out, leaving a perfect cavity. Careful wax removal keeps the mold intact.

- Molten brass is poured into the mold at controlled temperatures. Gravity, vacuum, or pressure methods help fill every detail.

- After cooling, workers break away the ceramic shell. They finish the casting by grinding and polishing to meet tight tolerances.

Proper control at each stage ensures brass castings are accurate, smooth, and free from defects.

Bronze Investment Casting Steps

Bronze investment casting uses a similar process, but with a few differences in melting and handling:

- Wax patterns are made by injection or 3D printing.

- Patterns are attached to a sprue, forming a tree.

- The tree is dipped in ceramic slurry and coated with layers for strength.

- Wax is removed by heating, leaving a clean cavity.

- The ceramic shell is sintered to boost strength and preheated before pouring.

- Molten bronze is poured into the mold.

- Once cooled, the ceramic shell is removed. Workers cut, clean, and finish the bronze casting.

Both brass and bronze investment casting share these steps, but the melting temperature and alloy handling differ.

Process Challenges and Considerations

Casting brass and bronze can bring up several challenges. Here’s a quick look at common issues and how foundries solve them:

| Defect Type | Common Challenges | Typical Solutions |

|---|---|---|

| Cracks | High iron or silicon, impurities, low mold temp, stress from design | Control alloy, adjust design, balance mold temp, even ejection force |

| Deformation | Poor design, early mold opening, thick gates, high mold temp | Improve design, adjust timing, optimize ejector pins, reduce gate thickness |

| Flow Marks | Thin metal layer, low mold temp, small sprue, low pressure | Raise temps, thicken runners, adjust speed and timing |

| Cold Shuts | Poor fusion, low temps, poor fluidity, long flow path | Increase temps, boost pressure, improve exhaust, use better alloys |

| Surface Colors/Spots | Bad release agents, contamination, wrong temps | Use quality agents, control spray, keep temps balanced |

| Reticulated Wings | Mold cracks, bad materials, temp differences, poor fluidity | Choose better materials, preheat mold, raise temps, improve gating and exhaust |

Tip: Careful control of temperature, mold design, and alloy composition helps prevent most casting defects.

Performance and Application Differences in Investment Casting

Mechanical Properties Comparison

Brass and bronze show clear differences in their mechanical properties when used in investment casting. Brass alloys, especially those with lead, offer great machinability and workability. They resist corrosion well and can handle many environments. The mechanical properties of brass, such as hardness and tensile strength, depend on how the casting cools and the mold’s thermal conductivity. Faster cooling creates finer grains, which boosts strength and ductility. This means brass investment castings can reach good tensile strength and stay flexible if the process is right.

Bronze, on the other hand, stands out for its hardness and strength. Bronze alloys, especially manganese bronze, can be as strong as steel. They resist wear and fatigue better than brass. Bronze also handles high stress and heavy loads without breaking down. Many bronze alloys can be heat treated to improve their properties even more, while brass usually cannot.

Here’s a quick comparison:

| Property | Brass | Bronze |

|---|---|---|

| Hardness | Lower hardness (softer) | Higher hardness (harder) |

| Ductility | Greater ductility (more malleable) | Lower ductility (more brittle) |

| Tensile Strength | Generally good, influenced by casting parameters | Generally good, but typically less ductile |

| Melting Point | ~900°C | ~950°C |

| Corrosion Resistance | Good, especially with manganese | Excellent, especially in saltwater |

Bronze also forms a protective patina over time, which helps prevent further corrosion. This makes bronze a top choice for parts that face harsh conditions or need to last a long time.

🛠️ Tip: Bronze investment castings can be heat treated for even better wear and fatigue resistance. Brass usually cannot be heat treated, so its properties depend more on the casting process.

Typical Applications for Brass Investment Casting

Brass investment casting works well for many industries. People choose brass for its corrosion resistance, strength, and shiny finish. The process allows for detailed shapes and smooth surfaces, which means less machining later.

Common uses include:

- Plumbing parts like valves, faucets, and pipe fittings

- Electrical connectors, terminals, and switch gears

- Fire protection equipment such as sprinkler heads

- Hardware for doors, windows, and decorative fixtures

- Automotive parts like radiator cores and engine connectors

- Marine hardware, including fittings and fasteners

- Musical instruments and jewelry

- Precision components for engineering and manufacturing

Brass investment casting is popular in construction, electrical, and decorative fields. The alloy’s good conductivity and resistance to tarnish make it ideal for both functional and attractive parts. Brass also offers a hygienic surface, which is important for plumbing and food-related equipment.

Brass investment casting lets manufacturers create complex, high-precision parts with smooth finishes. This saves time and money on extra machining.

Typical Applications for Bronze Investment Casting

Bronze investment casting shines in industries that demand strength, durability, and corrosion resistance. Bronze alloys handle tough jobs, especially where parts face water, chemicals, or heavy loads.

You’ll find bronze investment castings in:

- Marine and offshore equipment: propellers, pump impellers, valve components, ship bearings, and bushings

- Automotive and transportation: bushings, bearings, gears, and brake system parts

- Aerospace: valve seats, sleeves, and electrical connectors

- Industrial machinery: pump and compressor parts, gear wheels, and valve bodies

- Electrical and electronics: switchgear, relay components, and terminals

Bronze’s ability to resist corrosion, especially in saltwater, makes it a favorite for marine and chemical environments. The alloy’s wear resistance and toughness help it outperform many steels in moving parts like gears and bearings. Bronze also offers thermal stability and self-lubricating properties, which reduce maintenance needs.

- Aluminum bronze works well for high-stress and impact applications.

- Silicon bronze provides self-lubricity and strength for valves and bearings.

- Manganese bronze stands out for its strength and wear resistance, making it ideal for gears and propellers.

Bronze investment casting produces dense, reliable parts with fine details. The wide range of bronze alloys lets engineers match the material to each job’s needs.

Cost and Availability in Investment Casting

Material Cost Comparison

Brass and bronze both come from copper, but their prices can differ. Brass usually costs less because zinc is cheaper than tin. Bronze, with its higher tin content, often has a higher price tag. The cost also depends on the alloy grade and the amount of extra elements like aluminum or silicon. Both materials are recyclable, which helps lower costs and supports eco-friendly manufacturing. Recycling tin bronze, for example, uses much less energy than making new metal and helps keep prices steady.

Production Cost Factors

Several things affect the cost of making brass and bronze parts with investment casting:

- Process Yield: Lower yields mean more wasted material and higher costs. Yields can range from 30% to 60%.

- Shell Making: The number and type of ceramic shell layers matter. Surface layers use expensive materials like zirconium sand. About two-thirds of shell making costs come from materials, with the rest split between energy and labor.

- Energy Consumption: Melting and shell making use a lot of fuel and power.

- Labor Requirements: Skilled workers are needed for shell making and finishing. More complex shapes need more labor.

- Post-Processing Difficulty: Parts that need extra cleaning or repairs cost more to finish.

Investment casting helps reduce waste by making parts close to their final shape, which saves both material and energy.

Market Availability

Brass and bronze alloys are easy to find worldwide. Many foundries offer a wide range of grades for different uses, from marine to decorative parts. Both alloys meet global standards like ASTM and DIN, so buyers can trust the quality. Supply chains are strong, with fast shipping and in-house tooling that can deliver parts in four to six weeks. Foundries also use low-lead or lead-free brass to meet safety rules. These alloys serve many industries, including plumbing, aerospace, and automotive, showing their broad demand and steady supply.

How to Choose: Brass vs. Bronze Investment Casting

Decision Factors for Material Selection

Choosing between brass and bronze for investment casting depends on several important factors. Each alloy brings its own strengths to the table. Here are some key points to consider:

- Brass contains copper and zinc, which gives it good strength and ductility. It is easier to machine and form into complex shapes.

- Bronze uses copper and tin, sometimes with aluminum or silicon. This makes it harder and more wear-resistant than brass.

- Both alloys resist corrosion, but bronze stands out in harsh environments like saltwater. Brass can corrode faster in these settings, especially if it faces dezincification.

- Mechanical demands matter. If a part needs to handle heavy loads or lots of wear, bronze is usually the better choice.

- Environmental exposure plays a big role. Bronze works well for marine hardware, while brass fits decorative or indoor uses.

- Cost comes after performance. Brass is usually less expensive, but bronze may last longer in tough conditions.

Environmental factors, such as exposure to saltwater or chemicals, can make a big difference. Bronze often lasts longer in these environments, reducing the need for replacements and lowering long-term costs.

Quick Reference Table

| Property / Aspect | Bronze | Brass | Notes / Summary |

|---|---|---|---|

| Composition | Copper (80-90%), Tin (10-20%), plus possible Pb, Ni, P | Copper (55-95%), Zinc (5-45%) | Bronze contains tin and sometimes other elements; brass contains zinc as main alloying metal. |

| Strength & Hardness | High (due to tin content) | Moderate | Bronze is stronger and harder than brass. |

| Corrosion Resistance | Excellent (especially marine) | Lower, zinc content can increase corrosion susceptibility | Bronze is preferred for marine and outdoor use. |

| Machinability | Low (hard, brittle) | High (excellent machinability) | Brass is easier to machine than bronze. |

| Electrical Conductivity | Low | Moderate | Brass conducts electricity better than bronze but less than copper. |

| Melting Point | ~913°C | ~930°C | Both have lower melting points than copper; brass slightly higher than bronze. |

| Casting Behavior | Good fluidity, captures details well | Good castability but zinc evaporation can be an issue | Bronze is more commonly used for casting intricate shapes. |

| Welding | Weldable with care (oxy-fuel, TIG) | Variable weldability; zinc can cause cracking | Welding brass can be challenging due to zinc evaporation. |

| Forming | Limited formability at room temp; hot forming possible | Excellent formability and ductility | Brass is easier to form into complex shapes. |

| Cost | Generally more expensive | Generally more cost-effective | Brass is usually cheaper than bronze. |

| Applications | Marine hardware, gears, bearings, sculptures, musical instruments (cymbals, bells) | Decorative hardware, musical instruments (trumpets, saxophones), ammunition casings, electrical connectors | Bronze favored for strength and corrosion resistance; brass favored for machinability and decorative use. |

Brass and bronze offer different strengths in investment casting. To choose the right material, they should consider part complexity, production volume, and surface finish needs. By following these decision factors, anyone can match their project’s demands, budget, and environment for the best results.

FAQ

What makes bronze better for marine parts?

Bronze resists saltwater corrosion much better than brass. This property helps bronze parts last longer on boats, ships, and docks.

Can you use brass and bronze castings outdoors?

Yes, both alloys work outside. Bronze handles harsh weather and moisture better. Brass looks great but may tarnish faster in wet or salty air.

Is investment casting with brass or bronze more expensive?

Bronze usually costs more because tin is pricier than zinc. Brass offers a budget-friendly option for many projects.