Understanding the market performance of pump body precision casting manufacturers helps stakeholders make informed decisions. It reveals how well a company meets industry needs in the realm of pump body precision investment casting. Factors like production capacity, innovation, and customer satisfaction play a big role in the success of a pump body precision investment casting factory. Manufacturers that invest in advanced technologies, like 3D printing, often deliver better products. Reliable quality control measures, such as ISO 9001 certifications, also build trust and improve market standing.

Key Takeaways

- Pay attention to product quality. Companies with ISO 9001 prove they care about trust and happy customers.

- Deliver on time to gain trust. Meeting deadlines keeps customers loyal and helps stay ahead of others.

- Check what customers say. Good reviews show strengths, while bad ones show what needs fixing, helping people decide better.

Key Metrics for Evaluating Pump Body Precision Casting Manufacturers

Production Quality and Standards

Production quality is the backbone of any pump body precision casting manufacturer. Companies that adhere to strict quality standards, such as ISO 9001, demonstrate their commitment to delivering reliable products. High-quality casting ensures durability and reduces the likelihood of defects. Manufacturers often achieve this by maintaining precise tolerances during the casting process. For instance:

- High precision tolerance enhances quality assurance, leading to better customer satisfaction.

- Maintaining a tolerance of less than 0.005 inches can reduce rework rates by up to 25% in precision-critical industries.

- Production accuracy of up to 99.5% is possible when manufacturers effectively track production cycles and equipment utilization.

These practices not only improve product reliability but also strengthen a company’s market reputation.

Delivery Timelines and Reliability

Timely delivery is crucial in the competitive world of pump body precision casting. Manufacturers that consistently meet deadlines build trust with their clients. Delays can disrupt supply chains and lead to financial losses for customers. Reliable manufacturers often invest in advanced scheduling systems and efficient logistics to ensure on-time delivery. By prioritizing punctuality, they enhance customer loyalty and maintain a competitive edge.

Customer Reviews and Satisfaction

Customer feedback offers valuable insights into a manufacturer’s performance. Positive reviews often highlight strengths like product quality, responsiveness, and after-sales support. On the other hand, negative feedback can reveal areas for improvement. Companies that actively address customer concerns and implement changes based on feedback tend to perform better in the market. Monitoring online reviews and testimonials can help stakeholders gauge a manufacturer’s reputation and reliability.

Financial Performance and Growth Indicators

A company’s financial health reflects its market performance. Metrics like revenue growth, profit margins, and return on investment (ROI) provide a clear picture of its stability and potential. Manufacturers with steady financial growth often reinvest in technology and infrastructure, further improving their capabilities. Stakeholders should also consider factors like market share and expansion into new regions, as these indicate a company’s adaptability and ambition.

Importance of Precision in Casting

Precision is a defining factor in pump body precision casting. It directly impacts the functionality and lifespan of the final product. Manufacturers that prioritize precision reduce material waste and minimize the need for rework. This not only lowers production costs but also enhances customer satisfaction. High precision levels, such as tolerances below 0.005 inches, ensure that the cast components meet stringent industry requirements. Precision-driven processes ultimately lead to better market performance and stronger customer trust.

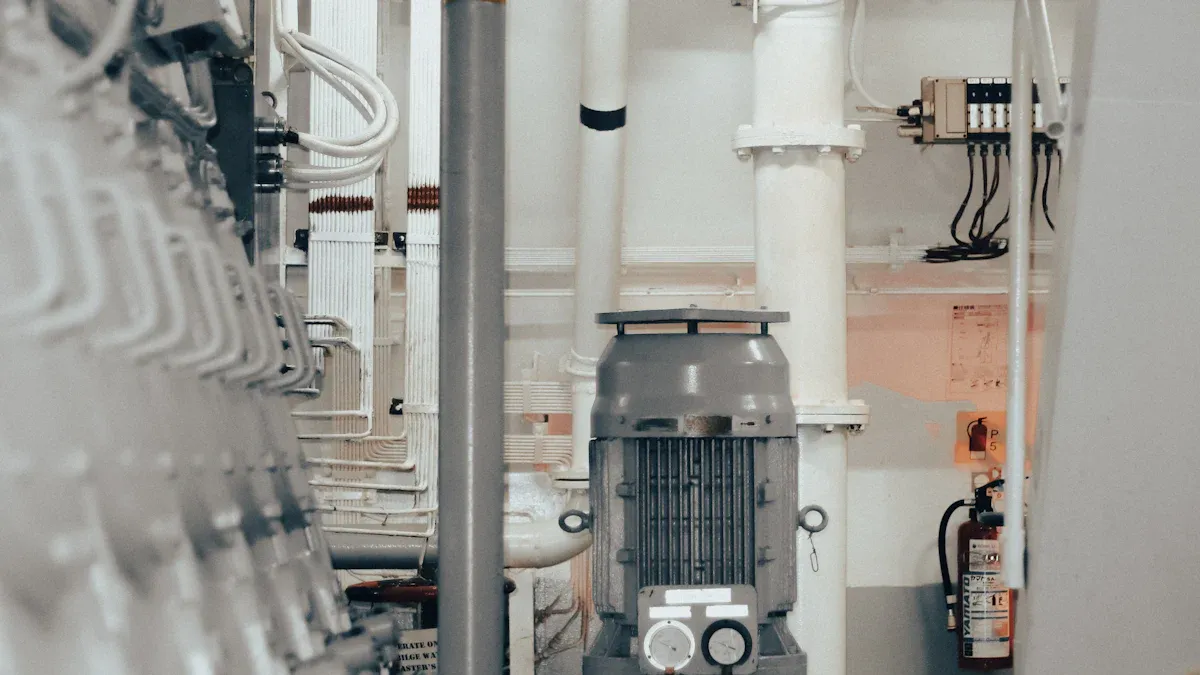

Evaluating Technological Advancements

Technological innovation plays a pivotal role in the success of pump body precision casting manufacturers. Companies that adopt advanced tools like 3D printing and automated casting systems often achieve higher efficiency and accuracy. The integration of technologies such as AI and IoT enables real-time monitoring and predictive maintenance, reducing downtime and improving productivity. Staying ahead in technology allows manufacturers to meet evolving industry demands and maintain a competitive advantage.

Industry Trends Impacting Pump Body Precision Casting

Adoption of Green Casting Practices

Sustainability is becoming a priority in manufacturing. Many companies now adopt green casting practices to reduce their environmental footprint. These practices include using recyclable materials, minimizing waste, and improving energy efficiency during production. For example, some manufacturers recycle sand used in molds, cutting down on resource consumption. Others invest in energy-efficient furnaces to lower emissions. Green casting not only benefits the planet but also appeals to eco-conscious customers. Companies that embrace these practices often gain a competitive edge in the market.

Integration of AI and IoT in Manufacturing

Artificial intelligence (AI) and the Internet of Things (IoT) are transforming the manufacturing landscape. Manufacturers use AI to optimize production schedules, predict equipment maintenance needs, and improve quality control. IoT devices enable real-time monitoring of machinery, ensuring smooth operations. For pump body precision casting, these technologies enhance accuracy and reduce downtime. Imagine a factory where sensors detect potential issues before they cause delays. That’s the power of AI and IoT in action. Companies leveraging these tools stay ahead of industry demands.

Advances in Material Innovation

Material innovation is reshaping the pump body precision casting industry. Manufacturers experiment with alloys and composites to create stronger, lighter, and more durable components. For instance, advanced stainless steel alloys resist corrosion better, extending the lifespan of pump bodies. Some companies explore ceramic-based materials for high-temperature applications. These innovations improve product performance and open doors to new markets. Staying updated on material trends helps manufacturers remain competitive.

Automation and Efficiency Improvements

Automation is revolutionizing manufacturing processes. Automated casting systems reduce human error and speed up production. Robots handle repetitive tasks, freeing workers to focus on more complex operations. For pump body precision casting, automation ensures consistent quality and faster delivery times. Efficiency improvements, like streamlined workflows and better inventory management, also play a role. Companies that invest in automation often see higher productivity and lower costs, making them more attractive to customers.

Practical Steps for Analyzing Pump Body Precision Casting Manufacturers

Researching Company Profiles and History

Understanding a manufacturer’s background is a great starting point. A company’s history often reveals its stability, expertise, and adaptability in the pump body precision casting industry. For instance, manufacturers with decades of experience tend to have refined processes and a deeper understanding of market demands. Reports from industry experts can provide both qualitative and quantitative insights into a company’s performance. These reports often highlight trends like investments in advanced technology or growth in export markets, which are critical indicators of a manufacturer’s potential.

Stakeholders should also look for milestones such as certifications, partnerships, or expansions into new regions. These achievements often reflect a company’s commitment to innovation and quality. By researching company profiles, stakeholders can identify manufacturers that align with their needs and values.

Comparing Services and Offerings

Not all manufacturers provide the same range of services. Some specialize in high-precision casting, while others focus on bulk production. Comparing their offerings helps stakeholders find the right fit for their requirements. Key factors to consider include:

- Customization Options: Does the manufacturer offer tailored solutions for unique specifications?

- Material Expertise: Can they work with advanced alloys or composites?

- Post-Production Services: Do they provide machining, finishing, or quality testing?

A detailed comparison ensures that stakeholders choose a manufacturer capable of meeting their specific needs. It also highlights areas where one company might have an edge over another, such as faster delivery times or better customer support.

Assessing Market Reputation and Customer Feedback

A manufacturer’s reputation speaks volumes about its reliability. Customer feedback, whether positive or negative, offers valuable insights into their strengths and weaknesses. Positive reviews often highlight consistent quality, timely delivery, and excellent customer service. On the other hand, recurring complaints might indicate issues like delays or subpar products.

Stakeholders can explore online forums, social media platforms, and industry-specific review sites to gather feedback. Companies that actively address customer concerns and improve based on feedback tend to perform better in the long run. A strong market reputation often correlates with higher customer satisfaction and loyalty.

Utilizing Online Resources and Reviews

The internet is a treasure trove of information for evaluating manufacturers. Websites like LinkedIn, Glassdoor, and industry-specific directories provide detailed profiles and reviews. Stakeholders can also explore case studies, white papers, and press releases to understand a company’s achievements and innovations.

For a more technical evaluation, stakeholders can refer to quality standards like MSS-SP-55 or MSS-SP-93. These standards outline methods for evaluating casting quality, such as visual inspections or liquid penetrant examinations. The table below summarizes some key standards:

| Standard Code | Description |

|---|---|

| MSS-SP-55 | Quality Standard for Steel Castings for Valves, Flanges, Fittings and Other Piping Components – Visual Method for Evaluation of Surface Irregularities |

| MSS-SP-93 | Quality Standard for Steel Castings and Forgings for Valves, Flanges, Fittings and Other Piping Components – Liquid Penetrant Examination Method |

| MSS-SP-94 | Quality Standard for Ferritic and Martensitic Steel Castings for Valves, Flanges, Fittings, and other Piping Components – Ultrasonic Examination Method |

| MSS-SP-147 | Quality Standard for Steel Castings Used in Standard Class Steel Valves-Sampling Method for Evaluating Casting Quality |

These resources help stakeholders make informed decisions based on objective criteria.

Benchmarking Against Competitors

Benchmarking involves comparing a manufacturer’s performance against its competitors. This process highlights areas where a company excels or falls short. Key metrics to evaluate include production quality, delivery timelines, and technological advancements. For example, a manufacturer that adopts automation and AI might outperform competitors in efficiency and precision.

Stakeholders can also analyze market share and growth trends. Companies expanding into new regions or industries often demonstrate adaptability and ambition. By benchmarking, stakeholders gain a clearer picture of a manufacturer’s standing in the market and its potential for future growth.

Evaluating pump body precision casting manufacturers requires a focus on key metrics, industry trends, and practical analysis steps. A systematic approach simplifies decision-making and ensures better outcomes. Staying informed about innovations and market shifts empowers stakeholders to make smarter choices. After all, knowledge is the key to staying ahead in this competitive industry.

FAQ

What certifications should a reliable manufacturer have?

Look for certifications like ISO 9001 for quality management and MSS-SP standards for casting quality. These ensure consistent production and adherence to industry standards.

How can stakeholders verify a manufacturer’s reputation?

Stakeholders can check online reviews, customer testimonials, and industry forums. Positive feedback and active engagement with customer concerns indicate a trustworthy manufacturer.

Why is precision so important in pump body casting?

Precision ensures durability, reduces material waste, and minimizes rework. High precision levels meet strict industry requirements, improving product performance and customer satisfaction.