Selecting optimal investment casting alloys is vital for project success. The alloy choice directly impacts part performance and longevity. Poor selections often cause costly failures and redesigns. For instance, an incorrect alloy might increase unit costs by 5–15%. Informed decisions prevent these expensive issues. For more information on our Products, Contact us.

Key Takeaways

- Choosing the right metal for your project is very important. It helps your part work well and last a long time.

- Think about where your part will be used. This helps you pick a metal that can handle heat, rust, or heavy use.

- Working with experts early saves money. They help you choose the best metal and avoid problems later.

Key Considerations for Selecting Investment Casting Alloys

Choosing the right alloy for your project involves careful thought. Engineers must consider several factors to ensure the final part performs as expected.

Operating Environment and Application Demands

First, engineers must understand where the part will operate. Will it face extreme temperatures, corrosive chemicals, or heavy loads? The environment often dictates the best alloy choice. A part used in a marine setting needs different properties than one in an aerospace engine.

Essential Mechanical Properties

Next, consider the part’s essential mechanical properties. These characteristics show how a component performs under stress. For example, strength measures how well a material handles forces without breaking or changing shape forever. This includes:

- Tensile Strength: Resistance to being pulled apart, crucial for components under pulling forces.

- Yield Strength: The point where a part starts to change shape permanently, vital for preventing lasting changes under load.

- Compressive Strength: Resistance to crushing, important for components under compressive forces.

- Shear Strength: Resistance to sliding or shearing, relevant for components experiencing cutting or shearing forces.

- Hardness: Resistance to scratching, important for surfaces with contact or friction.

- Ductility: Ability to deform without fracturing, allowing bending or stretching without breaking.

- Toughness: Capacity to absorb energy and resist fracture, especially under impact, crucial for components subjected to sudden shocks.

- Fatigue Strength: Ability to withstand repeated stress cycles without failure, essential for components experiencing cyclic loading.

Corrosion and Wear Resistance Needs

Corrosion and wear resistance are also very important. Centrifugal casting makes stainless steels resist corrosion better. It does this by making them denser. Many alloys protect parts very well.

- Brass and bronze show great corrosion resistance.

- Copper-based alloys generally resist corrosion well.

- Beryllium-copper provides high corrosion resistance over long periods.

- Stainless steels are highly corrosion resistant due to a minimum of 10.5% chromium content.

- Cobalt-based superalloys offer superior corrosion resistance compared to nickel-based options.

Thermal Performance Requirements

Parts often need to perform well in certain temperatures. Does the part work in very hot conditions? Will it heat up and cool down quickly many times? Some alloys stay strong and whole even in extreme heat. Others might bend or lose their useful traits.

Cost-Effectiveness and Manufacturability

Finally, consider cost-effectiveness and manufacturability. Specialized alloys greatly increase material costs for investment casting. Their basic price is much higher than common carbon steel. Superalloys, like Inconel, cost much more per pound. Alloys that melt at higher temperatures also need more energy. This increases electricity use. These alloys also need more expensive, special materials for molds and furnaces. Reactive alloys, like titanium, need special air during pouring. This stops them from reacting with oxygen. This adds more steps and cost to the process.

Common Investment Casting Alloys and Their Properties

Choosing the right material is a big step in investment casting. Different alloys offer unique benefits. They suit various applications based on their properties. Let’s explore some common investment casting alloys and what makes them special.

Stainless Steel Investment Casting Alloys

Stainless steel is a popular choice for investment casting. It offers a great mix of strength, durability, and corrosion resistance. This makes it reliable in many temperatures. You often find stainless steel parts in medical devices, marine hardware, food processing equipment, and pump housings. These are places needing high hygiene or strong corrosion resistance.

The most common grade is 304 (CF-8). It has low carbon, about 18% chromium, and at least 8% nickel. This mix helps it resist scaling and corrosion even at high temperatures. Its low carbon content means you can weld it without extra heat treatment, even in harsh conditions. All 300 series stainless steels contain nickel. Nickel helps them stay strong and flexible at high temperatures. It also makes them easy to weld. People often use 304 for strong parts in critical industries and tough environments. Other popular grades include 316, 304L/316L, 410, 416, and 17-4.

| Grades | Features | Applications |

|---|---|---|

| 304 | Austenitic, >8% Ni, food grade, most widely used, good for less corrosive air environments. | Medical, food industry, chemical industry, mechanical equipment, pipe industry, automotive industry. |

| 316 | Austenitic, >10% Ni, better corrosion resistance than 304, suitable for marine or harsh chemical environments. | Fire fighting, auto parts, marine hardware, chemical, pipeline, construction, decoration, food industry. |

| 304L / 316L | Similar mechanical properties to 304/316, lower carbon content for increased ductility, good welding performance, and reliable corrosion resistance, higher price. | Food, chemical, medical, plumbing. |

| 410 & 416 | Martensitic, high strength, good processing, high heat treatment hardness, no Ni, weak corrosion resistance. | Auto parts, tools, knives. |

| 17-4 PH | Martensitic, 3%-5% Ni, good corrosion resistance, highest strength in stainless steel series, used for non-deforming products. | Military, medical, mechanical components, machine tools, turbine blades. |

| 2205 | Duplex (22% Cr, 2.5% Mo, 4.5% Ni-N), high strength, good impact toughness, good overall and local stress corrosion resistance. | Sporting, pump & valve industry. |

17-4 PH stainless steel investment castings are known for their high strength, hardness, and excellent fatigue properties. They offer superior mechanical properties, including great strength, durability, and wear resistance. You can heat-treat them to make these properties even better. This happens through a process called precipitation hardening. It involves aging the steel at specific temperatures, like 900-1350 degrees Fahrenheit. This stabilizes its structure and makes it more resistant to changing shape. The aging time is very important for getting the right hardness and mechanical properties.

| Property | Condition | Value Range |

|---|---|---|

| Tensile Strength (PSI) | Age-Hardened (H1350M) | 115,000 to 180,000 |

| Yield Strength (PSI) | Age-Hardened (H1350M) | 140,000 to 160,000 |

| % Elongation | Age-Hardened (H1350M) | 6 to 20 |

| Hardness Range | Age-Hardened (H1350M) | 26 to 40 Rc |

Carbon and Low Alloy Steel Investment Casting Alloys

Carbon and low-alloy steel investment castings are widely used for structural parts. They offer strength, hardenability, and resistance to wear and abrasion. These steels are also relatively affordable. The investment casting process adds value by creating complex shapes with high integrity and tight tolerances. This often reduces or removes the need for welding and machining.

Low alloy steels provide excellent strength and durability for structural components. Manufacturers add elements like chromium, nickel, molybdenum, and vanadium to improve mechanical properties. This gives them great tensile strength, impact resistance, and toughness. They are perfect for critical parts that face high stress and harsh conditions.

The investment casting process creates complex shapes with high precision using low alloy steels. This accuracy allows for intricate designs and tight tolerances. These are crucial for meeting strict performance and safety rules. The method helps make parts with fine details, thin walls, and complex inner structures. Other manufacturing methods often struggle to achieve these features.

Low alloy steel investment casting helps reduce weight without losing strength. This is great for improving fuel efficiency. Designers can make lightweight yet strong parts by optimizing design and material properties. This allows for hollow or lattice-structured parts. They keep their strength while reducing overall weight. This leads to better fuel economy and lower emissions.

Investment casting with low alloy steel is also cost-effective. It uses a “near-net-shape” manufacturing approach. This greatly reduces the need for machining and finishing after casting. It saves material, machining time, and labor costs. Making many identical parts in one go also boosts efficiency and scalability. This lowers overall production costs.

Low alloy steel investment castings offer better wear resistance and longer fatigue life. This is important for structural parts under constant stress, friction, and wear. Elements like chromium and molybdenum increase the material’s hardness and wear resistance. This extends the life of critical parts like gears and shafts. It also reduces the need for frequent replacements or repairs.

To get the right hardness, carbon steel investment castings often undergo heat treatment.

- Carburize Case Hardening makes the surface of castings hard while keeping the core softer and tougher. It adds carbon to the surface of low carbon steels at high temperatures (1500 to 1650 degrees F).

- Annealing involves heating and slow cooling. This improves ductility, softness, and machinability. It also relieves internal stresses. Carbon steel cast components often use this process.

- Normalizing heats metal to a high temperature and cools it in the air. This refines the grain structure, improves tensile strength, and makes the part more stable in size. Carbon steel components often use this.

- Quenching and Tempering rapidly cools heated metal to increase hardness and strength. However, this can make it brittle. Tempering then reheats the metal at lower temperatures and cools it slowly to restore toughness. Many steel investment castings use this combined process.

Aluminum Investment Casting Alloys

Aluminum alloys are lightweight and offer a high strength-to-weight ratio. This makes them popular in many industries.

- A356 aluminum is lightweight, resists corrosion well, and is durable. It has high strength and ductility. It contains aluminum (92.5%), copper (0.20%), iron (0.20%), magnesium (0.35%), manganese (0.10%), silicon (7%), and zinc (0.10%). You can heat-treat it (T5 and T6) to make it harder.

- A357 aluminum is easy to cast and has a high strength-to-weight ratio.

- F357 aluminum is lightweight, easy to weld, and handles different temperatures well.

Here is a look at some aluminum alloys and their properties:

| Aluminum Alloy | Tensile Strength (PSI) | Yield Strength (PSI) | % Elongation |

|---|---|---|---|

| 319 | 23,000–31,000 | 13,000–20,000 | 1–5 |

| 355 | 35,000–50,000 | 28,000–39,000 | 1–3 |

| C355 | 35,000–50,000 | 28,000–39,000 | 1–3 |

| 356 | 32,000–40,000 | 22,000–30,000 | 3–7 |

| A356 | 32,000–45,000 | 28,000–36,000 | 2–5 |

| A357 | 38,000–50,000 | 28,000–40,000 | 2–5 |

| F357 | 38,000–50,000 | 28,000–40,000 | 2–5 |

Other notable aluminum alloys include:

- A356 Aluminum Alloys: These contain pure aluminum and silicon with small amounts of magnesium, iron, copper, zinc, and manganese. They offer high strength, good elongation, and excellent ductility. Many consider them all-purpose aluminum.

- F357 Aluminum Alloys: These are foundry-grade metals mainly containing aluminum, silicon, and magnesium. They are known for high strength and heat treatability. They can replace alloys containing beryllium.

- C355 Aluminum Alloys: These are cast-grade aluminum with higher copper levels, along with aluminum, silicon, iron, magnesium, manganese, zinc, and titanium. They have very high strength, good weldability, and corrosion resistance, but are less ductile than A356.

- ALSi10Mg Alloys: These are age-hardened cast aluminum alloys. Heat treatment improves their strength. They feature high corrosion resistance, mechanical strength, and low density.

- BS L99: This alloy follows British Standards. It undergoes solution and precipitation treatment. It contains aluminum, silicon, and magnesium, offering high corrosion resistance and good machining properties.

- BS L169: Another British Standard aluminum grade, artificially aged and solution treated. It flows very well, making it suitable for thin-walled castings. It also has good strength and machinability.

Aluminum investment castings are preferred in many areas. You find them in electronics, military, aerospace, food and dairy, dental, and medical equipment manufacturing. Specific items include pistol frames, levers, medical devices, valves, and heat sinks. In the automotive sector, aluminum investment castings are chosen for parts needing both durability and precision. These include engine parts, transmission elements, and suspension systems. Their light weight makes them especially desirable for these uses.

Copper and Bronze Investment Casting Alloys

Copper and bronze investment casting alloys offer unique properties. Copper has superior thermal and electrical conductivity. This makes it valuable for applications needing efficient heat or electricity transfer. Common copper alloys include high conductivity copper, chromium copper, beryllium copper, aluminum bronze, and copper-nickel.

Bronze alloys show increased strength and corrosion resistance due to their tin content, especially in saltwater. Bronze is harder and resists corrosion better, particularly in seawater. It also stands up better to wear and metal fatigue. Over time, bronze forms a protective layer called a patina. This helps prevent further corrosion. This makes it a top choice for harsh conditions. Bronze’s ability to resist corrosion in saltwater makes it ideal for marine and chemical environments.

Specific bronze alloys offer different benefits:

- Manganese Bronze: This alloy has good corrosion resistance. Manufacturers use it in marine hardware.

- Silicon Bronze: This offers excellent corrosion resistance, especially in marine environments. People use it for marine fittings.

- Nickel Tin Bronze (Nickel-Aluminum Bronzes): This provides exceptional corrosion resistance. It resists impingement and cavitation very well. Engineers specify it for demanding marine components.

Nickel-Based Superalloys for Investment Casting

Nickel-based superalloys are known for their strength in extreme heat and excellent corrosion resistance. They maintain high tensile and yield strength, ensuring strong performance. Components made from these alloys offer lasting durability, which improves equipment reliability. They also resist fatigue and creep deformation, providing long-term stability.

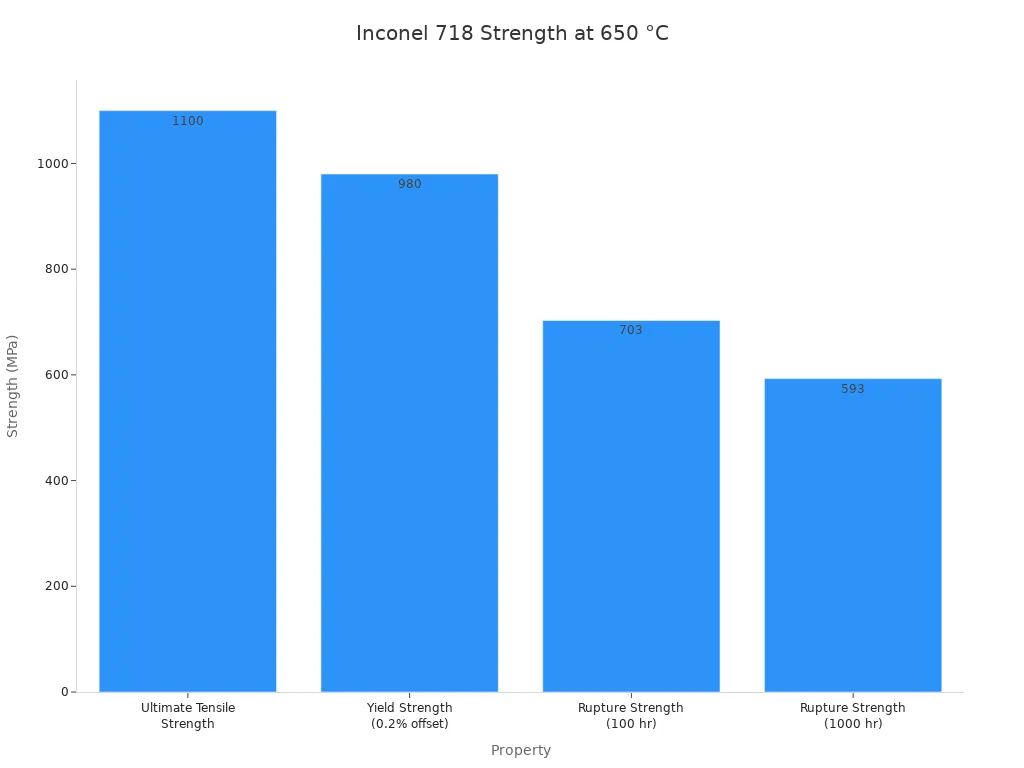

Inconel 718 is a prime example. It maintains structural integrity up to 1300°F (704°C). This makes it perfect for critical parts in jet engines and gas turbines within aerospace and energy sectors. These industries need high strength and resilience to extreme temperatures. Inconel 718 also shows excellent tensile and impact strength.

Nickel-based superalloys find many uses in aerospace. Inconel 100 castings are ideal for turbine engine parts because of their high strength-to-density ratio. Inconel 100 is often used for aerospace and defense castings due to its exceptional properties, including hardness. It is best suited for turbine blade casting and making various turbine engine components among nickel-based alloys. Single-crystal nickel-based superalloys are also used for high-pressure turbine blades in aerospace applications.

Cobalt-Based Superalloys for Investment Casting

Cobalt-based superalloys, like Stellite, are known for their excellent wear resistance. Stellite 1 has a dense, face-centered cubic (FCC) cobalt matrix. Chromium and tungsten-based carbides reinforce this matrix. This gives it superior hardness and wear resistance. Its high carbon content creates a structure that resists deformation, even in extreme conditions. Stellite 1 stays mechanically stable and resists fatigue and creep up to 870°C. This makes it suitable for high-friction and high-temperature environments.

Stellite 21 consists of a CoCrMo alloy matrix with hard carbides spread throughout. These carbides strengthen the alloy and increase its hardness. It shows excellent resistance to cavitation, galling, and metal-to-metal sliding wear. However, Stellite 21 is not recommended for severe hard particle abrasion because it has fewer carbides.

The hard carbides in these alloys, like chromium and tungsten-based ones, are stable at high temperatures. They maintain hardness and excel in abrasive wear resistance. Elements like tungsten and molybdenum dissolve in the cobalt matrix. This increases hardness and wear resistance, especially in high-stress environments. The cobalt base metal matrix provides high-temperature stability. It can also change between FCC and HCP crystal structures. This helps it absorb energy and reduce wear.

Cobalt-based superalloy investment castings are used in medical applications. They are often found in medical investment castings generally, and in wear-resistant applications within the medical industry. Cobalt investment castings are commonly used in medical implants. They are designed for intense wear and stress. Specific uses include orthopedic applications, surgical implant applications (like Co-26Cr-6Mo), and metal-on-metal hip prostheses.

Matching Project Requirements with Investment Casting Alloys

A Systematic Alloy Selection Process

Choosing the right alloy for a project needs a clear plan. Engineers follow a step-by-step process. First, they define the part’s job. They look at its operating environment and what it must do. Then, they list all the required properties. This includes strength, how it handles heat, and if it needs to resist rust. Next, they research different investment casting alloys that meet these needs. They compare each alloy’s pros and cons. Finally, they pick the best one. This careful method helps ensure the part works well.

Balancing Performance, Cost, and Production Volume

Finding the perfect alloy often means making choices. Engineers must balance how well a part performs with its cost. They also consider how many parts they need to make. A high-performance alloy might cost more. It could also be harder to work with. For small batches, a more expensive alloy might be okay. For large production runs, cost becomes a bigger factor. Sometimes, a slightly less perfect alloy saves a lot of money. This balance helps keep projects on budget. It also ensures the final product meets market demands.

The Role of Post-Casting Treatments

After casting, parts often need more work. Post-casting treatments improve their properties. Heat treatments are very common. They change the metal’s structure. For example, hardening and tempering make steel stronger. This process involves heating steel to high temperatures, over 780°C. Then, tempering toughens the steel and removes brittleness. This improves fatigue life and wear resistance. Vacuum solution annealing protects stainless steel surfaces during high-temperature processing. It works for duplex and precipitation grades. Precipitation hardening, also called age hardening, makes certain alloys harder. This includes some stainless steels, aluminum, and copper-based alloys. It follows a solution annealing treatment. Then, one or more aging processes achieve the desired hardness.

Other treatments also help. Normalizing and annealing make steel more uniform. They improve machinability and remove internal stresses. Homogenization holds the casting at a high temperature. This allows alloying elements to spread evenly. Stress equalizing/relieving heats the casting below its recrystallization temperature. This releases internal stresses. Surface hardening processes, like gas nitriding, increase surface hardness. These happen in controlled atmospheres. Tempering or annealing can also lower hardness. They promote recrystallization. These treatments are crucial for getting the best from investment casting alloys.

Importance of Prototyping and Testing

Before making many parts, engineers always test prototypes. This step is very important. It confirms the chosen alloy and design work as expected. Various tests check different aspects of the part. For example, tensile testing measures yield strength and ultimate tensile strength. It shows how much force a part can handle before breaking. Hardness testing, like Rockwell or Brinell, checks how resistant the surface is to dents. Charpy V-notch impact testing measures a material’s toughness. It shows how much energy it absorbs before fracturing.

Other tests look inside the material. Radiographic testing (X-ray) finds internal flaws. Liquid penetrant inspection (LPI) reveals surface cracks. Macroscopic examination provides a visual check. Microscopic examination checks microstructure, grain size, and inclusion ratings. This ensures the material quality. These tests help engineers find problems early. They prevent costly failures later in production. Prototyping and thorough testing save time and money. They ensure the final product is safe and reliable.

Expert Guidance for Investment Casting Alloys Selection

When to Consult Casting Specialists

When should you seek expert help? You should consult casting specialists early in your project. Metallurgists have deep knowledge about how different metals behave. They understand their characteristics. Their expertise ensures you select the correct materials for the casting process. They also guarantee the chosen materials and the resulting casting meet required quality standards. This prevents costly mistakes later.

Benefits of Early Supplier Collaboration

Collaborating with your supplier early offers big advantages. An experienced foundryman states, “the earlier a client involves their foundry partner in the design of a new part, the more time and money they save.” This early involvement can lead to significant cost reductions. For example, one project saw costs drop from $200,000-$300,000 to just $6,000-$15,000. This saving came from using QuickCast patterns, which allowed for faster prototyping and design optimization.

Exploring Custom Alloy Solutions

Sometimes, standard options do not meet specific project needs. In these cases, exploring custom alloy solutions becomes necessary. Specialists can help develop unique metal compositions. These custom investment casting alloys can provide properties not found in off-the-shelf materials. This ensures your part performs exactly as required for highly specialized applications. Custom alloys are often developed for extreme environments or very specific performance criteria. This approach offers maximum flexibility for challenging designs.

Strategic alloy selection profoundly impacts a product’s performance and cost. It ensures optimal material choice, meeting specifications and minimizing post-processing.

Key Insight: A study on the importance of choosing correct investment casting materials emphasizes that the right material not only achieves desired functionality but also eliminates unnecessary costs and defects.

Invest time and effort in material selection to unlock precision casting’s full potential.

Expert Insight: “Proper material selection will ultimately help you achieve the desired functionality of your design. It can cut costs and material waste.”

Consult casting specialists early for the best outcomes.

FAQ

What is the most important factor when choosing an alloy?

The operating environment and application demands are most important. They dictate the necessary properties for the part. Consider where the part will function.

Can you always use a standard alloy for every project?

Not always. Some projects need custom alloy solutions. These are for specific performance or extreme conditions. Specialists can develop unique metal compositions.

Why is testing prototypes important for alloy selection?

Testing prototypes confirms the chosen alloy and design work as expected. It helps find problems early. This prevents costly failures later in production.