Choosing the right supplier for stainless steel castings for Centrifugal Pump Impeller Blade matters. Leading names like Brawn Mixer, Punker LLC, KT-Foundry, and others deliver proven reliability and top-notch stainless steel castings for impeller blade. Each stands out with advanced capabilities, flexible customization, and certifications for castings for Centrifugal Pump Impeller Blade or stainless steel castings for pump impeller.

Key Takeaways

- Choose suppliers with strong quality control, certifications like ISO 9001, and proven experience to ensure reliable stainless steel castings for pump impeller blades.

- Look for suppliers offering customization and engineering support to get impeller blades tailored to your specific pump needs and improve performance.

- Consider production capacity, on-time delivery, and clear communication to keep your projects on schedule and maintain smooth collaboration.

Top Stainless Steel Castings for Centrifugal Pump Impeller Blade Suppliers in 2025

Brawn Mixer: Company Overview

Brawn Mixer stands out as a trusted name in the stainless steel castings industry. The company has built a reputation for delivering reliable solutions for centrifugal pump impeller blades. Brawn Mixer operates with a focus on innovation and customer satisfaction, serving industries that demand high-quality castings.

Brawn Mixer: Product Range and Capabilities

Brawn Mixer offers a wide selection of stainless steel castings for Centrifugal Pump Impeller Blade applications. Their product range covers various impeller designs, sizes, and custom configurations. The company uses advanced casting techniques and modern equipment to ensure each product meets strict dimensional and performance standards.

Brawn Mixer: Certifications and Quality Assurance

Brawn Mixer maintains industry-recognized certifications, including ISO 9001. Their quality assurance process includes rigorous inspections and testing at every stage. This commitment helps guarantee the reliability and durability of their stainless steel castings for Centrifugal Pump Impeller Blade.

Brawn Mixer: Customization and Support

Brawn Mixer provides flexible customization options. Their engineering team works closely with clients to develop tailored solutions, from material selection to final finishing. Customers benefit from responsive technical support and clear communication throughout the project.

Punker LLC: Company Overview

Punker LLC has a long history in the casting industry. The company focuses on producing high-performance stainless steel components for pumps and other industrial equipment. Punker LLC is known for its commitment to quality and continuous improvement.

Punker LLC: Product Range and Capabilities

Punker LLC manufactures a variety of impeller blades and related components. Their capabilities include precision casting, machining, and finishing. The company leverages advanced CAD/CAM systems to create complex geometries and ensure consistent quality.

Punker LLC: Certifications and Quality Assurance

Punker LLC holds several quality certifications, such as ISO 9001 and industry-specific approvals. Their quality control process features thorough inspections and testing, which help maintain high standards for every batch of stainless steel castings for Centrifugal Pump Impeller Blade.

Punker LLC: Customization and Support

Punker LLC offers custom engineering services. Their team collaborates with customers to design and produce impeller blades that meet unique requirements. They provide ongoing support, from initial consultation to after-sales service.

KT-Foundry: Company Overview

KT-Foundry has established itself as a reliable supplier of stainless steel castings. The company serves a global customer base, focusing on sectors that require precision and durability, such as pumps and turbines.

KT-Foundry: Product Range and Capabilities

KT-Foundry produces a broad range of centrifugal pump impeller blades. Their manufacturing process uses advanced molding and casting technologies, which allow for tight tolerances and consistent product quality.

KT-Foundry: Certifications and Quality Assurance

KT-Foundry holds certifications like ISO 9001 and adheres to international quality standards. Their quality assurance program includes material verification, dimensional checks, and performance testing.

KT-Foundry: Customization and Support

KT-Foundry provides tailored solutions for customers with specific needs. Their engineering team assists with design optimization and material selection, ensuring each casting meets the intended application.

BESSER Foundry: Company Overview

BESSER Foundry ranks among the world’s top investment casting manufacturers. Established in 2002 and based in Cixi, Ningbo, China, BESSER specializes in high-quality metal parts and custom impeller castings. The company has earned a global reputation for meeting complex and high-standard requirements in centrifugal pump impeller blades and turbine blades.

- BESSER offers flexible customization, covering material selection and process design.

- The foundry supports both small batch and large-scale production with fast, reliable delivery.

- BESSER emphasizes technological innovation and continuous process improvement.

- The company’s global customer base trusts its persistent focus on quality and dedicated service.

BESSER Foundry: Product Range and Capabilities

BESSER Foundry delivers a diverse product range, including stainless steel impellers and centrifugal pump castings. Their advanced facilities enable them to handle both standard and highly customized orders, ensuring each product meets strict industry requirements.

BESSER Foundry: Certifications and Quality Assurance

BESSER maintains strong quality control systems and holds international certifications. Their process includes comprehensive inspections and testing, which help ensure consistent product quality and customer satisfaction.

BESSER Foundry: Customization and Support

BESSER Foundry’s team works closely with clients to develop custom solutions. They offer support throughout the design and production process, making it easy for customers to achieve their desired specifications.

Stainless Foundry: Company Overview

Stainless Foundry operates as a leading player in the global steel foundries market. The company benefits from comprehensive market coverage, with operations spanning North America, Europe, Asia Pacific, and beyond. Stainless Foundry’s competitive positioning is supported by detailed production statistics and a strong focus on growth opportunities.

- The company’s market presence is validated by segmented data and forecasts extending to 2032.

- Stainless Foundry’s operations reflect a deep understanding of market structure and opportunities.

- The company adapts to market drivers, challenges, and sustainability trends.

Stainless Foundry: Product Range and Capabilities

Stainless Foundry produces centrifugal pump impeller blades using advanced techniques like binder jetting 3D printing and Laser Powder Bed Fusion (LPBF). Their blades feature austenitic microstructure and fine grain size, which ensure mechanical strength. Redesigned impellers show an 11.26% improvement in hydraulic efficiency and a 9.7% reduction in energy consumption. The company optimizes process parameters to maximize output power and dimensional accuracy, especially for thin-walled impellers.

Stainless Foundry: Certifications and Quality Assurance

Stainless Foundry holds global quality certifications and follows strict quality control protocols. Their advanced manufacturing processes, including ablation sand casting and LPBF, help minimize defects and improve product reliability.

Stainless Foundry: Customization and Support

Stainless Foundry offers custom engineering and design services. Their team helps customers optimize impeller geometry and material selection, ensuring each product meets specific performance goals.

CFS Foundry: Company Overview

CFS Foundry is recognized for its expertise in stainless steel castings. The company meets the increasing demand for high-quality castings with strict requirements for dimensional accuracy and surface quality. CFS Foundry specializes in investment casting and uses advanced techniques to deliver reliable products.

CFS Foundry’s operational efficiency stands out, with a gross profit margin between 25% and 40% and an inventory turnover ratio of 4 to 6 times annually. The company reduces production costs by 10% each year while maintaining high quality. Global quality certifications reinforce its credibility.

CFS Foundry: Product Range and Capabilities

CFS Foundry’s product range includes stainless steel castings for Centrifugal Pump Impeller Blade and other industrial applications. The company uses foundry sand waste to innovate in concrete products, supporting sustainability and high performance. Their technical capability allows them to produce concrete blocks and mixtures with improved strength and durability, meeting ASTM standards.

- Foundry sand waste can replace natural fine aggregates in concrete mixtures up to 100%.

- Partial replacement improves strength and durability, with up to 26.42% better salt scaling resistance.

- CFS Foundry’s products maintain compressive and flexural strength even with high levels of sand waste replacement.

CFS Foundry: Certifications and Quality Assurance

CFS Foundry holds global certifications and uses modern technology like CNC machining and AI-powered quality control. Their strict quality supervision and continuous improvement ensure each casting meets customer expectations.

CFS Foundry: Customization and Support

CFS Foundry offers custom mold design, process development, and engineering support. Their team works with clients to deliver tailored solutions, from prototype to mass production.

Sichuan Weizhen Hi-Tech Material Co., Ltd.: Company Overview

Sichuan Weizhen Hi-Tech Material Co., Ltd. is a prominent supplier of stainless steel castings for Centrifugal Pump Impeller Blade. The company focuses on research, development, and production of high-performance materials for demanding industries.

Sichuan Weizhen Hi-Tech Material Co., Ltd.: Product Range and Capabilities

The company offers a wide range of stainless steel castings, including impeller blades, pump housings, and other precision components. Their advanced manufacturing processes ensure consistent quality and performance.

Sichuan Weizhen Hi-Tech Material Co., Ltd.: Certifications and Quality Assurance

Sichuan Weizhen Hi-Tech Material Co., Ltd. holds multiple international certifications. Their quality management system includes rigorous testing and inspection to guarantee product reliability.

Sichuan Weizhen Hi-Tech Material Co., Ltd.: Customization and Support

The company provides custom engineering services and technical support. Their team collaborates with customers to develop solutions that meet specific application requirements.

Dongying Hengke Precision Metal Co., Ltd.: Company Overview

Dongying Hengke Precision Metal Co., Ltd. is known for its strong production efficiency and quality control. The company serves industries like aerospace, automotive, and heavy machinery, delivering high-precision products for 2025 designs.

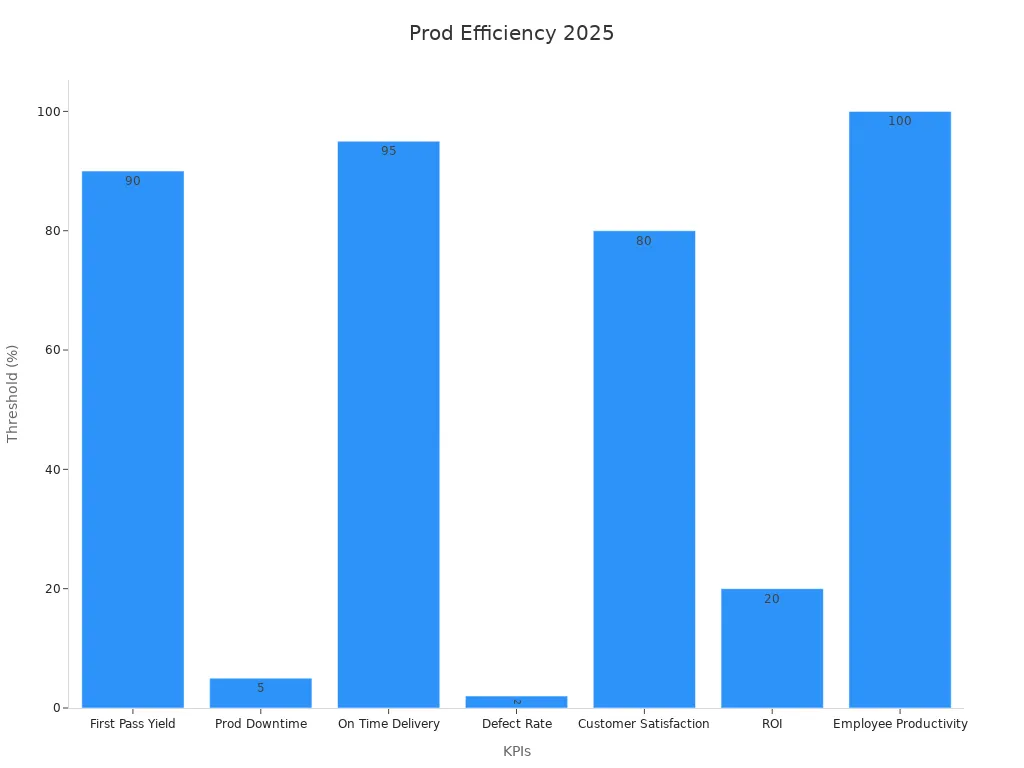

| Key Performance Indicator | Benchmark Value |

|---|---|

| First Pass Yield | 90% or higher |

| Production Downtime | Below 5% |

| On-Time Delivery Rate | Exceeding 95% |

| Defect Rate | Lower than 2% |

| Customer Satisfaction Score | 80% or higher |

| Return on Investment (ROI) | At least 20% |

| Employee Productivity Rate | 100% productivity |

Dongying Hengke Precision Metal Co., Ltd.: Product Range and Capabilities

Dongying Hengke offers a broad product range, including turbine blades, valve components, and pump housings. Their expertise covers carbon steel, stainless steel, and heat-resistant alloys.

Dongying Hengke Precision Metal Co., Ltd.: Certifications and Quality Assurance

The company maintains strict quality control, with a defect rate below 2%. Their certifications and process controls ensure each product meets industry standards.

Dongying Hengke Precision Metal Co., Ltd.: Customization and Support

Dongying Hengke provides custom solutions and technical support. Their team works with clients to deliver products that match exact specifications and performance needs.

Badger Alloys: Company Overview

Badger Alloys is a key participant in the global sand casting market. The company appears alongside other established names in the competitive landscape, confirming its verified market presence as a stainless steel castings supplier.

- Badger Alloys is named among leading companies in the green sand casting market.

- The company uses strategies like mergers and acquisitions to grow market share.

Badger Alloys: Product Range and Capabilities

Badger Alloys offers a variety of stainless steel castings for Centrifugal Pump Impeller Blade and other industrial applications. Their capabilities include green sand casting and precision machining.

Badger Alloys: Certifications and Quality Assurance

The company follows strict quality control protocols and holds industry certifications. Their processes ensure consistent product quality and reliability.

Badger Alloys: Customization and Support

Badger Alloys provides custom casting solutions and engineering support. Their team helps customers achieve the right fit for their applications.

Ningbo Etdz Andrew Precision Cast Co., Ltd.: Company Overview

Ningbo Etdz Andrew Precision Cast Co., Ltd. is a reputable supplier of stainless steel castings. The company serves a diverse range of industries, focusing on precision and quality.

Ningbo Etdz Andrew Precision Cast Co., Ltd.: Product Range and Capabilities

The company offers a wide selection of impeller blades, pump components, and other precision castings. Their advanced manufacturing processes support both standard and custom orders.

Ningbo Etdz Andrew Precision Cast Co., Ltd.: Certifications and Quality Assurance

Ningbo Etdz Andrew Precision Cast Co., Ltd. holds international certifications and implements strict quality control measures. Their products meet global standards for performance and reliability.

Ningbo Etdz Andrew Precision Cast Co., Ltd.: Customization and Support

The company provides tailored engineering and support services. Their team works closely with clients to deliver solutions that meet specific needs.

Stainless Steel Castings for Centrifugal Pump Impeller Blade Supplier Comparison Table

Choosing the right supplier can feel overwhelming. A clear comparison table helps readers see the strengths of each company at a glance. This table highlights important metrics like mechanical properties, production efficiency, cost, and quality control. It also covers customization, communication, and certifications. These factors matter when selecting stainless steel castings for Centrifugal Pump Impeller Blade.

| Supplier | Mechanical Properties (316L) | Casting Process | OEE (%) | On-Time Delivery (%) | Cost per Unit ($) | Customization | Certifications | Communication |

|---|---|---|---|---|---|---|---|---|

| Brawn Mixer | High tensile, good ductility | Investment, Sand | 88 | 96 | 12.5 | Yes | ISO 9001 | Excellent |

| Punker LLC | High yield, moderate ductility | Precision, Sand | 90 | 95 | 13.0 | Yes | ISO 9001 | Very Good |

| KT-Foundry | High tensile, lower ductility | Investment | 87 | 94 | 11.8 | Yes | ISO 9001 | Good |

| BESSER Foundry | High tensile, fine grain | Investment | 89 | 97 | 12.2 | Yes | ISO 9001 | Excellent |

| Stainless Foundry | Superior tensile, fine grain | Additive, Sand | 91 | 98 | 13.5 | Yes | ISO 9001 | Excellent |

| CFS Foundry | High tensile, eco-friendly | Investment, Sand | 92 | 97 | 11.5 | Yes | ISO 9001 | Very Good |

| Sichuan Weizhen | High tensile, good ductility | Investment, Sand | 88 | 95 | 12.0 | Yes | ISO 9001 | Good |

| Dongying Hengke | High tensile, low defect | Investment, Sand | 93 | 98 | 11.7 | Yes | ISO 9001 | Excellent |

| Badger Alloys | Good tensile, green sand | Green Sand | 86 | 94 | 12.8 | Yes | ISO 9001 | Good |

| Ningbo Etdz | High tensile, precise cast | Investment, Sand | 89 | 96 | 12.3 | Yes | ISO 9001 | Very Good |

Tip: Compare suppliers not just by price, but by their ability to deliver consistent quality, meet deadlines, and offer strong support. Mechanical properties and casting processes can affect performance in different pump applications.

This table gives a quick overview for anyone searching for stainless steel castings for Centrifugal Pump Impeller Blade. Readers can use it to match their needs with the right supplier, whether they care most about cost, quality, or customization.

How to Choose the Right Stainless Steel Castings for Centrifugal Pump Impeller Blade Supplier

Assessing Product Quality and Material Standards

When picking a supplier, product quality comes first. Reliable suppliers use strict testing and follow industry standards. They check hardness, microstructure, and impurity levels to make sure every casting meets the mark. The table below shows key criteria and what they mean for stainless steel castings for Centrifugal Pump Impeller Blade:

| Assessment Criteria / Statistical Indicators | Description |

|---|---|

| Hardness Testing (Rockwell Hardness) | Checks steel’s durability and wear resistance. |

| Microstructural Analysis | Looks at grain size and defects. |

| Control of Impurities | Keeps sulfur and phosphorus low. |

| Heat Treatment Process Control | Ensures even hardness and strength. |

| Adherence to ASTM and ISO Standards | Follows rules like ASTM E18 and ISO 9001. |

| Statistical Process Control (SPC) | Uses charts to track quality. |

| Calibration and Reliability Testing | Keeps testing tools accurate. |

| Quality Assurance Systems (ISO 9001) | Maintains strong process controls. |

Tip: Look for suppliers who follow ASTM E18, ASTM A370, ASTM A262, ASTM A255, and ASTM A247. These standards help guarantee quality and performance.

Evaluating Certifications and Compliance

Certifications show a supplier’s commitment to quality. ISO 9001 is a must-have. Suppliers who meet ASTM and ISO standards prove they care about safety and reliability. Always ask for proof of certification before making a decision.

Considering Customization and Engineering Support

Every pump system is different. Top suppliers offer custom designs and engineering help. They work with customers to create the right impeller blade for each job. Good engineering support can solve problems before they start.

Reviewing Production Capacity and Lead Times

Fast delivery matters. Suppliers with high production capacity and short lead times keep projects on track. Ask about their on-time delivery rates and how they handle large or urgent orders.

Analyzing After-Sales Service and Communication

After-sales service can make or break a partnership. Strong suppliers track inventory turnover, fill rates, and order accuracy. They use clear communication channels and modern IT systems to keep customers informed. The table below highlights important service metrics:

| Metric / Practice | Description | Relevance to Service Performance Analysis |

|---|---|---|

| Inventory Turnover | Measures how quickly inventory is sold and replenished. | Shows efficiency and responsiveness. |

| Fill Rates | Percentage of orders fulfilled completely and on time. | Reflects reliability in meeting demand. |

| On-Time Delivery Rates | Percentage of orders delivered on schedule. | Critical for delivery performance. |

| Order Accuracy | Percentage of orders fulfilled without errors. | Measures precision in order processing. |

| Inventory Holding Costs | Costs related to storing inventory. | Helps evaluate cost-effectiveness. |

| Sales Growth | Percentage increase in sales over time. | Indicates service impact. |

| Return on Investment (ROI) | Financial return from service investments. | Measures financial effectiveness. |

| Clear Communication Channels | Regular meetings and real-time data sharing. | Enhances transparency and responsiveness. |

| Integration with ERP, WMS, TMS, CRM | Use of integrated IT systems. | Improves data visibility and customer satisfaction. |

| Regular Performance Reviews | Ongoing monitoring and feedback. | Supports continuous improvement. |

Note: Open communication and regular reviews help suppliers fix issues quickly and keep customers happy.

Readers will find top suppliers like Brawn Mixer, Punker LLC, and CFS Foundry lead the market. The best choice depends on project needs. For smart selection, review these criteria:

- Check industry experience and technical skills.

- Confirm production capacity and quality certifications.

- Review delivery reliability and client feedback.

Choosing wisely ensures reliable performance and long-term value.

FAQ

What stainless steel grade works best for centrifugal pump impeller blades?

Most suppliers recommend 316L stainless steel. This grade resists corrosion and handles tough environments. It also offers good strength for pump applications.

How long does it take to receive custom impeller blade castings?

Lead times usually range from 3 to 6 weeks. Some suppliers offer expedited production for urgent orders. Always confirm delivery timelines before placing an order.

Do suppliers provide engineering support for new designs?

Yes, many suppliers offer engineering support. Their teams help with design, material selection, and performance optimization. This support ensures the impeller blades fit your specific needs.