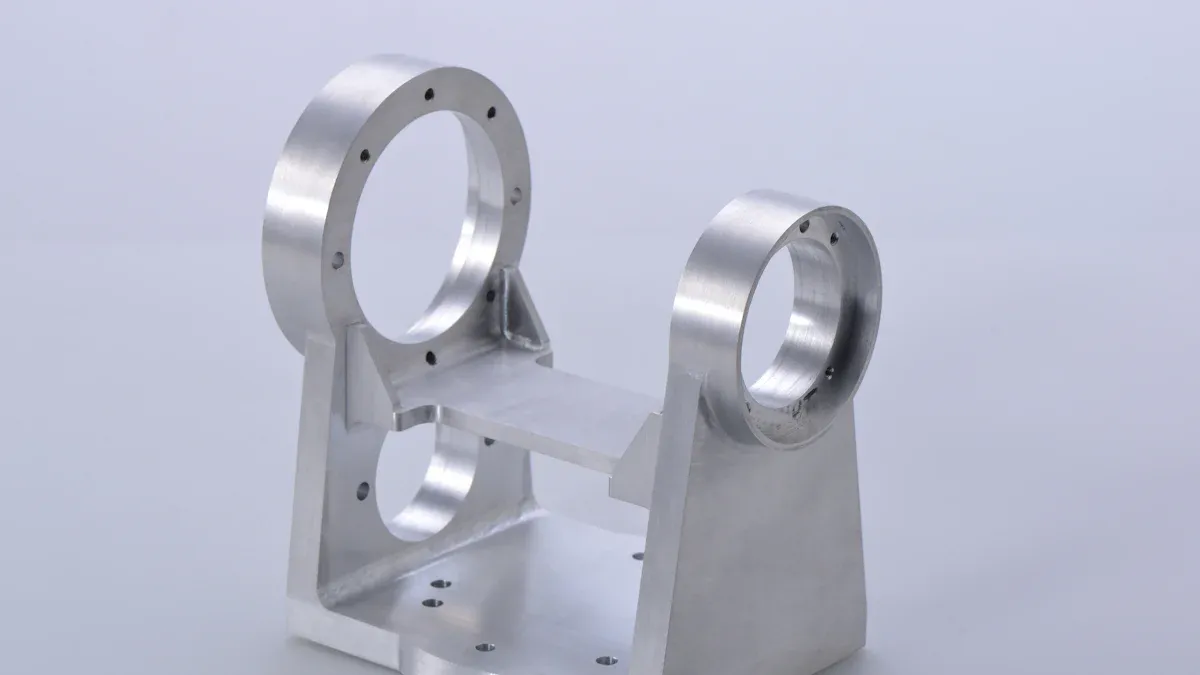

Evaluating 17-4 PH stainless steel casting from Mashine za Pingheng can be quite complex. Its unique microstructure and mechanical properties set it apart from other stainless steel alloys. Misconceptions often cloud the evaluation process, leading to inaccurate outcomes. Accurate metallurgical assessments are crucial for ensuring the reliability of our products made from this versatile material. For more information, feel free to contact us.

Njia muhimu za kuchukua

- Understand that 17-4 PH stainless steel has moderate corrosion resistance. Always assess environmental conditions before selecting materials to avoid failures.

- Recognize that the strength and hardness of 17-4 PH can vary based on heat treatment. Engineers should not assume uniform performance across all castings.

- Utilize advanced testing techniques like microhardness testing and X-ray diffraction to accurately evaluate 17-4 PH stainless steel. These methods help identify potential issues early.

Common Misconceptions About 17-4 PH Stainless Steel Casting

Misbeliefs on Corrosion Resistance

Many people mistakenly believe that 17-4 PH stainless steel casting offers superior corrosion resistance compared to other stainless steels. While it does provide moderate resistance, it doesn’t perform as well as austenitic stainless steels in highly corrosive environments. This misunderstanding can lead to improper material selection in industrial applications. For instance, if engineers choose 17-4 PH for a project requiring high corrosion resistance, they might face unexpected failures.

Ncha: Always consider the specific environmental conditions when selecting materials.

Recent studies have shown that 17-4 PH stainless steel can be susceptible to pitting and stress corrosion cracking. For example, one study found that additively manufactured (AM) samples exhibited higher rates of stable pit propagation due to reversed austenite. This indicates that under certain conditions, the corrosion resistance of 17-4 PH may not meet expectations.

| Study | Findings |

|---|---|

| Susceptibility to Pitting and EAC | AM samples showed higher propagation kinetics of stable pits due to reversed austenite, indicating reduced corrosion resistance under stress. |

| Pitting corrosion of 17-4 PH | LBM samples had a higher nucleation rate of metastable pits, suggesting increased corrosion susceptibility compared to wrought stainless steels. |

Assumptions Regarding Strength and Hardness

Another common misconception is that 17-4 PH stainless steel casting always provides superior strength and hardness. While this alloy does have impressive mechanical properties, the actual performance can vary significantly based on heat treatment and manufacturing processes.

For instance, aging treatments can dramatically affect yield strength. Engineers often assume that all 17-4 PH castings will perform similarly, but this isn’t the case. The growth of copper-rich precipitates during aging can enhance yield strength by hundreds of megapascals.

| Kipengele | Maelezo |

|---|---|

| Aging Treatments | Significant impact on yield strength, with measurable strengthening occurring within seconds at peak aging temperature (900 °F / 482 °C). |

| Precipitate Characteristics | The growth of copper-rich precipitates during aging can increase yield strength by hundreds of megapascals. |

| Differences in Properties | Notable differences exist between wrought and additively manufactured variants, affecting overall mechanical behavior. |

Moreover, actual strength and hardness measurements can contradict commonly held beliefs. For example, under specific heat treatment conditions, the minimum yield strength can vary significantly.

| Heat Treatment Condition | Minimum Yield Strength (ksi) | Minimum Tensile Strength (ksi) | Minimum Elongation (%) |

|---|---|---|---|

| H900 | 155 | 170 | 8 |

| H1150 | 115 | 140 | 10 |

Challenges in Metallurgical Evaluation of 17-4 PH Stainless Steel Casting

Variability in Material Properties

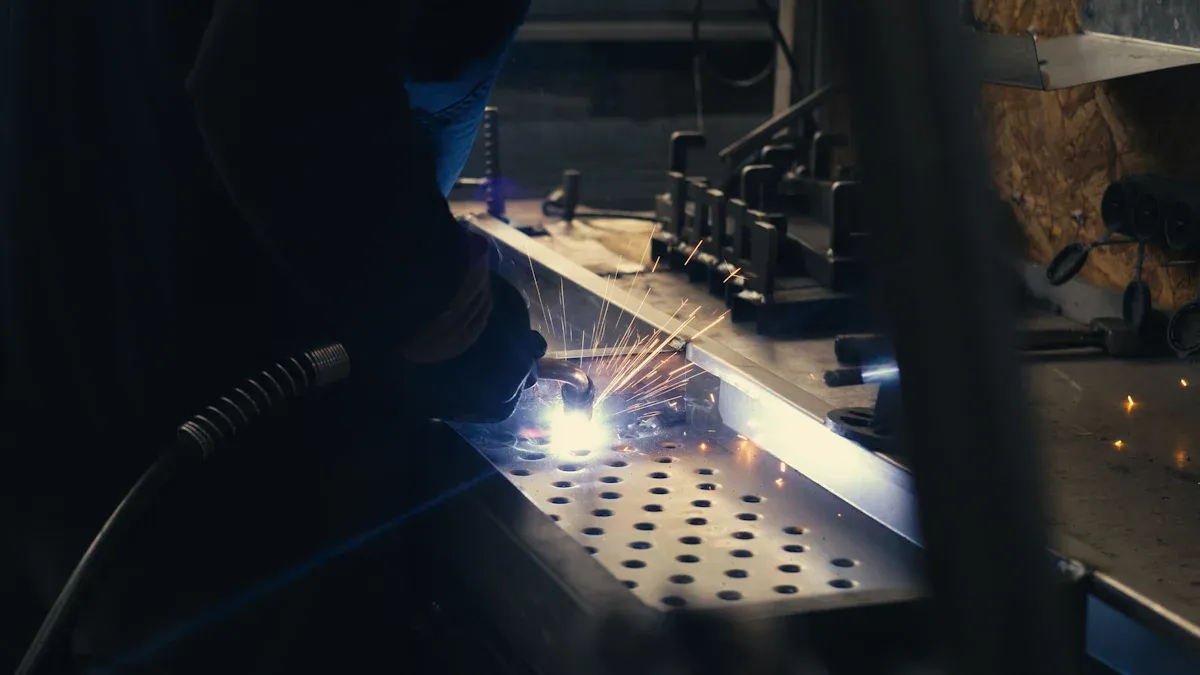

Evaluating 17-4 PH chuma cha pua casting presents unique challenges, primarily due to variability in material properties. This variability often stems from differences in the manufacturing processes. Here are some key factors that contribute to this inconsistency:

- The physical properties of 17-4 PH stainless steel can change based on the microstructures developed during production. Factors like porosity, pore shape, and grain size play significant roles.

- Low porosity levels are essential for indicating alloy strength. However, the consistency of porosity across different parts can greatly affect material properties.

- The mechanical behavior and density of 17-4 PH stainless steel can vary significantly depending on the process parameters used during production.

Studies show that these variations can lead to significant differences in mechanical properties, especially when comparing additive manufacturing (AM) with traditional wrought methods. For example, retained austenite and the effects of post-processing heat treatments are crucial in determining the final properties of the material. One study highlighted that optimizing the AMS 5355 homogenization heat treatment on AM 17-4 steel is vital for achieving a uniform microstructure similar to that of wrought counterparts.

Limitations of Standard Testing Methods

Standard testing methods for 17-4 PH stainless steel casting often fall short in accurately assessing material properties. Here are some limitations to consider:

- MEX samples typically show higher microhardness values than PBF-LB/M samples, with differences of up to 19% in certain planes.

- PBF-LB/M samples generally exhibit lower porosity compared to MEX samples, indicating better structural integrity.

- The density of PBF-LB/M samples is usually much higher than that of MEX samples, suggesting superior structural homogeneity.

- MEX samples often demonstrate lower surface roughness than PBF-LB/M samples, which indicates better surface quality.

These discrepancies highlight the need for advanced evaluation techniques. A technical report identified several challenges in metallurgical evaluation, including:

| Challenge | Maelezo |

|---|---|

| Phase Control | Controlling phase transformations during additive manufacturing poses significant challenges. |

| Retained Austenite | This phase can be present in amounts up to 100%, impacting mechanical properties. |

| δ-Ferrite Presence | High levels of δ-ferrite can lead to deterioration of printed part properties. |

| Variability | Residual phase fractions can vary with printing parameters, machines, and technologies, creating uncertainties. |

These challenges can significantly impact the final quality and performance of 17-4 PH stainless steel casting products. For instance, after laser shock peening (LSP) treatment, improvements in microhardness and wear properties were observed, showcasing the importance of proper evaluation methods.

Effective Evaluation Methods for 17-4 PH Stainless Steel Casting

Advanced Testing Techniques

To ensure the reliability of 17-4 PH stainless steel casting, advanced testing techniques play a crucial role. These methods help identify potential issues before they lead to failures. Here are some effective techniques:

- Microhardness Testing: This method assesses the hardness of small areas, providing insights into material properties.

- X-ray Diffraction (XRD): XRD helps analyze phase composition, revealing the presence of retained austenite and other phases that can affect performance.

- Scanning Electron Microscopy (SEM): SEM allows for detailed examination of microstructures, helping to identify defects and grain boundaries.

Using these advanced techniques can significantly reduce the risk of failure in applications. For instance, inadequate hardness levels in holding yokes often stem from high amounts of retained austenite due to improper heat treatment. By employing these testing methods, engineers can catch such issues early.

Importance of Microstructural Analysis

Microstructural analysis is vital for understanding the properties of 17-4 PH stainless steel casting. This analysis reveals how the material’s microstructure influences its mechanical behavior. Key aspects include:

- Grain Size: Smaller grains typically enhance strength and toughness.

- Phase Distribution: The presence of different phases, like martensite and austenite, can impact overall performance.

- Porosity Levels: High porosity can lead to weaknesses, making it essential to evaluate this aspect during production.

Moreover, techniques like double and triple aging processes can improve ductility and elongation without sacrificing tensile strength. This approach addresses common failure issues, ensuring that the final product meets performance expectations.

Case Studies and Real-World Implications of 17-4 PH Stainless Steel Casting

Industry Applications

17-4 PH stainless steel casting finds its way into various industries due to its unique properties. Here are some common applications:

- Industrial Equipment: Manufacturers use it in shafts, pumps, gears, and tools because of its load-bearing capacity and moderate corrosion resistance.

- Mafuta na gesi: Components like fasteners and drilling equipment benefit from its strength and toughness, making it ideal for harsh environments.

- Pharmaceutical and Medical: This alloy is crucial in dental equipment, orthopedic implants, and surgical instruments, where reliability is paramount.

- Defense and Aerospace: Engineers rely on it for missile components, aircraft fittings, and structural parts, where performance and safety are critical.

Lessons Learned from Evaluations

Real-world evaluations of 17-4 PH stainless steel casting reveal important lessons. A comparison between conventional manufacturing (CM) and additive manufacturing (AM) highlights key findings:

| Key Findings | Conventional Manufacturing (CM) | Additive Manufacturing (AM) |

|---|---|---|

| Ductility | Juu | Chini |

| Fatigue Limit | 640 MPa | 300 MPa |

| Defects | Ndogo | Significant porosity |

| Strain-life Curves | Kink point observed | Kink point observed |

Inaccurate evaluations can lead to serious issues, such as part failures and increased costs. This is especially true in critical industries like aerospace and nuclear, where the material’s strength and stability are vital for safety.

By learning from these evaluations, engineers can make informed decisions, ensuring that 17-4 PH stainless steel casting meets the demands of various applications.

Evaluating 17-4 PH stainless steel casting presents several challenges. Misconceptions about its properties can lead to poor material choices. Addressing these misunderstandings is crucial for engineers and manufacturers. They should explore advanced evaluation methods to ensure reliability and performance. Continuous research will enhance the understanding and application of this versatile alloy.

Maswali

What is 17-4 PH stainless steel used for?

17-4 PH stainless steel is commonly used in aerospace, medical, and industrial applications due to its strength and corrosion resistance.

How does heat treatment affect 17-4 PH stainless steel?

Heat treatment significantly alters the mechanical properties, enhancing strength and hardness while affecting ductility.

Can 17-4 PH stainless steel be welded?

Yes, 17-4 PH stainless steel can be welded, but proper techniques and preheat conditions are essential to avoid cracking.