投资铸造快速原型制作 正在改变公司生产复杂零件的方式。和 精密铸造快速原型制作,企业经历了更快的开发,提高了原型质量并降低了成本。许多行业(尤其是汽车和航空航天)取决于 铸造快速原型制作 对于小批量的高精度铸造需求。此方法可以快速设计调整,并有助于有效地完成苛刻的截止日期。

Key Takeaways

- 投资铸造快速原型制作 加快设计和生产的速度,让团队更快地创建和测试复杂零件,同时降低成本并减少错误。

- 选择正确的原型制作方法和材料可以提高表面质量,准确性和灵活性,从而帮助公司满足紧迫的截止日期和独特的设计需求。

- 遵循最佳实践,例如仔细的图案处理,模具制备和使用模拟工具,可导致更高质量的铸件 较少的缺陷 和生产更顺畅。

投资快速原型制作的主要好处

更快的设计迭代

公司现在可以在创纪录的时间内从概念转变为原型。通过3D打印的图案和数字工作流程,团队可以快速测试和完善设计。许多制造商报告说,他们可以在短短几天而不是几周内生产原型。这种速度使工程师可以尽早发现错误并进行改进,而无需等待昂贵的工具。例如,诸如Demir Engineering和Döktas之类的公司已使用快速原型来提供更快的替代零件和新产品,从而使项目步入正轨。

减少交货时间

投资铸造快速原型制作 削减传统的交货时间。行业基准表明,曾经花了6到8周的时间仅需几天。一些设施甚至在24小时内提供零件。这种加速有助于公司响应紧急需求,并减少昂贵的停机时间。 Decco Castings和KSB India都看到了交付速度的显着提高,这使他们的客户满意。

增强设计灵活性

设计师通过这种方法享有更多的自由。它们可以创建复杂的形状,薄壁和内部特征,而其他方法则很难或不可能。 SLA QuickCast® 和类似的技术使生产复杂的几何形状和测试不同的材料变得容易。下表突出显示了一些最重要的好处:

| Benefit | 解释 |

|---|---|

| 设计灵活性和复杂形状 | 实现制造方法难以或不可能的复杂,有机和薄壁的零件。 |

| 物质效率 | 近网状铸造减少了材料废物,对于昂贵的合金尤其重要。 |

| 出色的结构完整性 | 铸件可以匹配锻炼材料的机械性能。 |

| 非破坏性测试兼容性 | 支持高融合检查方法,对安全敏感行业至关重要。 |

| 低容量和原型生产 | 3D打印的蜡模式可快速,低成本的原型制作和一次性生产。 |

| 战略灵活性 | 双重过程规格可提高供应链灵活性。 |

早期开发节省成本

早期项目受益于较低的成本。快速原型消除了对昂贵工具的需求,并减少了材料浪费。团队可以在完整生产之前发现设计缺陷,从而节省后期修复的资金。公司还节省了劳动力并加快上市时间。这种方法支持小批量运行,非常适合需求有限或频繁更新的产品。

比较投资铸造快速原型的方法

选择正确的图案制作方法可以对您从中获得的结果产生很大的影响 投资铸造快速原型制作。每种技术都有自己的优势,局限性和最佳使用场景。让我们分解最受欢迎的选项,看看它们如何堆叠。

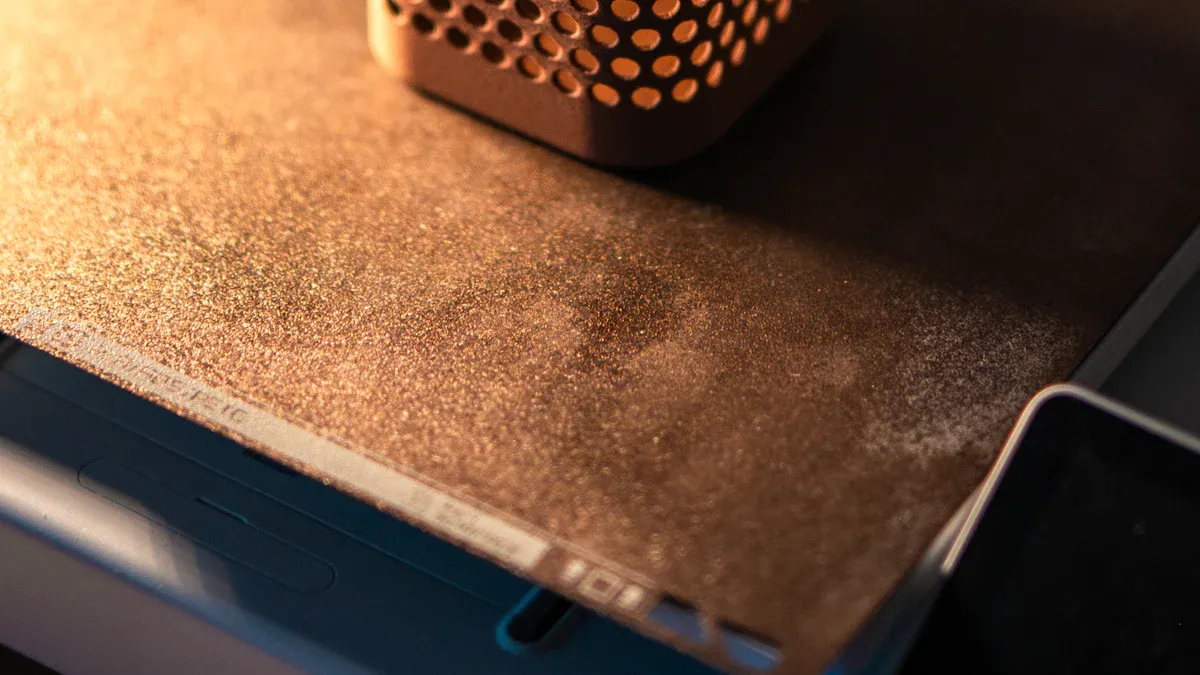

3D打印蜡图案

3D打印的蜡图案已成为许多铸造厂的最爱。像3D系统这样的公司使用Multijet打印(MJP)创建100%蜡模式,这些蜡模式恰好适合传统的投资铸造工作流程。这些图案像标准蜡一样融化并燃烧出来,因此无需更改铸造过程。这些模式提供了高分辨率,细节详细至25微米。他们还留下了倦怠后最少的残留物,这有助于防止最后一部分缺陷。

蜡图案适用于复杂形状和薄壁。它们支持复杂的几何形状,并且可以处理大小零件。但是,蜡模式的填充密度很重要。较低的填充比(5%-20%)是最好的,因为它们降低了在倦怠过程中霉菌破裂的风险。较高的填充物会使图案更强,但由于膨胀而导致壳破裂。较轻的图案也更快地打印并使用较少的材料,从而节省了时间和金钱。

提示: 为了获得最佳效果,请保持较低的填充比,以避免外壳破裂并提高霉菌的完整性。

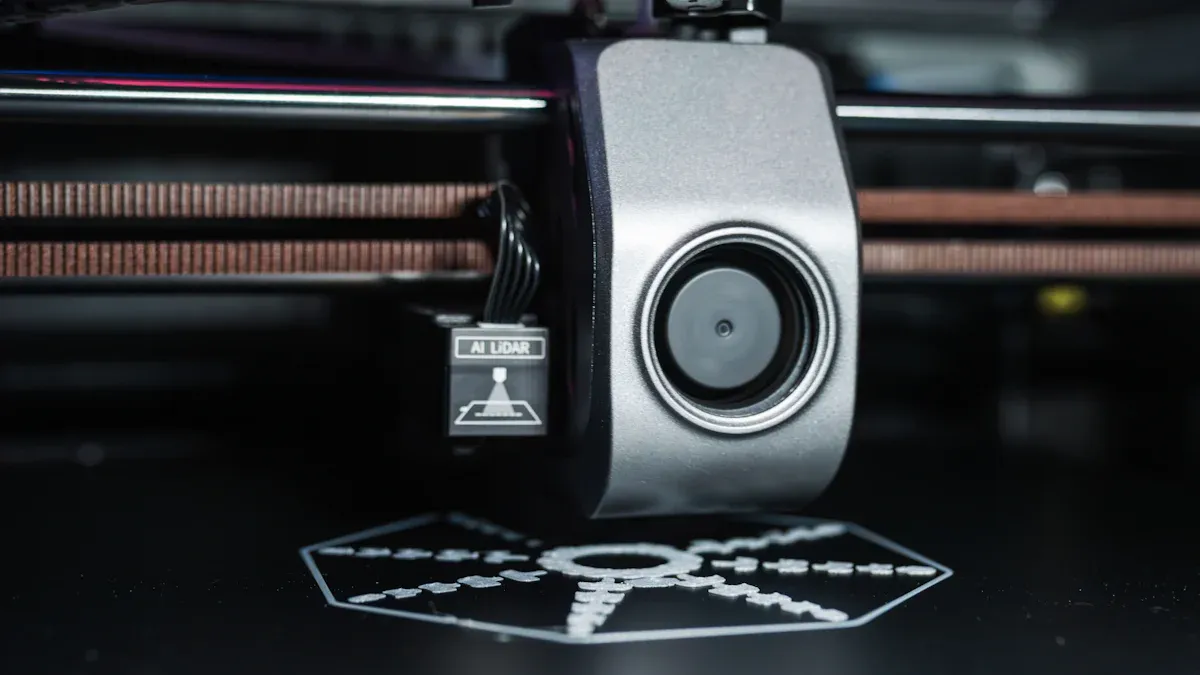

立体光刻(SLA)模式

SLA图案使用液体树脂和激光桶来逐层建造零件。该方法以其高分辨率和光滑的表面效果而闻名。 SLA模式可以捕获细节,并产生最小各向异性的零件。例如,QuickCast®技术会创建轻巧的半空心图案,几乎没有灰烬干净地燃烧。

当您需要小的,复杂的零件具有优质的表面质量时,SLA会发光。这些图案足以加工,可以用作金属铸造的主图案。生产很快 - 有时在一天之内。但是,SLA图案的成本超过FDM模式,并且需要额外的步骤,例如洗涤,干燥和固化。光聚合物树脂可能会粘稠,因此必须仔细处理。

| 方面 | 优势 | 缺点 |

|---|---|---|

| 维度的准确性 | 高,优于蜡模式 | 早期的Sla蜡模式很脆 |

| 表面饰面 | 优秀,光滑(低至12.5 µm) | 光聚合物可能粘稠 |

| 生产速度 | 快速,灵活的设计更改 | 需要后处理 |

| 成本 | 低于传统蜡的某些项目 | 高于FDM |

| 图案结构 | 半空心减少壳破裂 | 早期的SLA蜡模式在倦怠中挣扎 |

融合沉积建模(FDM)模式

FDM使用加热的喷嘴挤出塑料细丝,一层建造图案。此方法的低成本和能够快速生产大图案的能力而脱颖而出。 FDM模式非常适合原型和小体积运行。他们消除了工具的需求,因此您可以在大约24小时内从CAD到图案。

主要缺点是表面饰面。由于分层的“楼梯”效果,FDM模式具有更粗糙的质感。这种粗糙度可以转移到最终的铸造中,因此通常需要后处理。精度低于SLA或蜡图案,但是诸如平滑站之类的整理技术可以使表面质量接近注入蜡的蜡。

| 方面 | FDM模式 | SLA /蜡模式 |

|---|---|---|

| 准确性 | 中等,通过完成 | 高,最小的完成需要 |

| 表面饰面 | 粗糙,需要平滑 | 光滑,准备铸造 |

| 生产时间和成本 | 快速,低成本,没有工具 | 成本更高,蜡设置更长 |

| 铸造中的物质行为 | 用最小的灰烬燃烧,需要发泄 | 蜡融化干净,不需要排气 |

投资铸造的直接增材制造

直接添加剂制造,例如直接金属激光烧结(DML),跳过了图案和模具步骤。打印机直接从CAD数据构建金属零件,逐层构建金属零件。这种方法允许使用传统方法很难制作复杂的形状和自由形式表面。

直接金属印刷具有高精度和设计自由度。它适用于小批量或自定义零件。但是,它具有更高的成本,更长的交货时间以及印刷后需要取消支持的需求。由于产出较慢和材料限制,该过程对于大量生产而言并不理想。某些材料(例如ABS)比其他材料更好,因为它们会降低倦怠过程中壳破裂的风险。

| 方面 | 功能 | 限制 |

|---|---|---|

| 生产方法 | 直接从CAD,没有工具 | 受材料和打印机尺寸的限制 |

| 几何和复杂性 | 很高,支持复杂的设计 | 大零件需要更长的印刷 |

| 解决方案和准确性 | 高,降至16微米 | 完成之前的各向异性特性 |

| 生产量表 | 非常适合原型和小批次 | 不适合批量生产 |

| 环境和运营 | 更干净,浪费少 | 需要后处理,材料限制 |

每种方法的优势和局限性

投资铸造快速原型的每种方法都为桌子带来了独特的东西。这是一个快速的比较,可以帮助您确定哪个最适合您的项目:

| 方法 | 优势 | 限制 |

|---|---|---|

| 3D打印蜡图案 | 高分辨率,干净的倦怠,适合传统工作流程,支持复杂的形状 | 必须管理填充比以避免外壳破裂;大图的成本更高 |

| SLA模式 | 出色的表面饰面,高精度,快速产生,灵活的设计变化 | 更高的材料成本需要后处理,粘性光聚合物 |

| FDM模式 | 低成本,快速生产,大型构建量,无需工具 | 粗糙的表面饰面,准确度较低,需要在铸造之前进行平滑 |

| 直接加成制造 | 直接金属零件,跳过图案/模具,高复杂性 | 高成本,较长的交货时间,不理想大规模生产,需要删除支持 |

快速原型制作方法使投资铸造更加易于访问和灵活。他们减少了交货时间和成本,尤其是对于小批量或复杂零件。但是,每种方法在准确性,表面表面处理和过程控制方面都有权衡。了解这些差异有助于团队为他们的需求选择最佳方法。

可行的提示,以优化投资铸造快速原型制作

设计验证和优化

设计验证是成功的核心 投资铸造快速原型制作。团队可以通过快速创建物理原型来尽早发现设计缺陷。这种方法可以帮助他们测试功能并在转到全面生产之前发现问题。快速原型支持迭代过程,因此工程师可以进行多个设计更改并快速测试每个版本。这个周期会带来更好的设计,而越来越多的惊喜。

- 早期的原型帮助参与参与的每个人都可以看到并触摸零件,从而使反馈更加容易。

- 较短的交货时间和较低的工具成本意味着团队可以尝试更多的想法而不会打破预算。

- 自定义变得简单,让公司满足独特的客户需求。

最近的研究表明,将拓扑优化与添加剂制造和投资铸造的设计规则相结合带来了更多好处。诸如SIMP方法和Abaqus拓扑优化模块之类的工具可帮助工程师创建复杂的蜡模式,而无需额外的工具。这些方法提高了准确性和表面效果,尤其是用于热处理的铸钢零件。

提示: 使用高级设计软件, 快速原型工具 早日验证和完善设计。这种方法节省了时间,削减成本并导致更好的产品。

原型制作模式的材料选择

选择正确的原型材料来进行原型制作模式,对最终结果有很大的不同。高分辨率3D打印材料(例如SLA树脂)允许使用非常细节的图案。这种细节均提高了表面表面处理和铸造原型的尺寸精度。

- 图案材料的热特性很重要。右玻璃过渡温度和低热膨胀的材料有助于防止壳的破裂和失真。

- 工程师经常使用空心或薄壁结构来减少热膨胀并保持霉菌的稳固。

- 用尼龙等纤维加固陶瓷贝壳可以提高壳强度并降低铸造过程中失败的风险。

- 图案材料的表面饰面和纹理直接影响最终产品的质量。

强度和延展性等机械性能也起作用。模式需要承受铸造过程的应力。选择与最终产品属性相匹配的材料会导致更可靠和精确的原型。

过程模拟和测试

仿真和测试工具可帮助团队预测和改善投资铸造快速原型制作的结果。虚拟原型软件(例如ESI Procast)允许工程师在制作一部分之前进行热,流动和压力分析。这一步骤减少了昂贵的反复试验,并有助于尽早发现潜在的缺陷。

| 工具/方法 | 目的/应用 | 结果/利益 |

|---|---|---|

| ESI PROCATS | 虚拟原型,缺陷预测 | 提高铸造产量和质量 |

| 3D激光扫描 | CAD和RP的几何学获取 | 准确的数字化模型 |

| CAD建模(STL格式) | RP和仿真的数据转换 | 直接用于原型制作和仿真 |

| 岩浆 | 模拟跑步者和门控系统 | 孔隙率降低,铸造质量更好 |

| RP蜡模式制造 | 直接打印蜡图案 | 提高精度和表面饰面 |

包括Wall Colmonoy和Rolls-Royce在内的许多公司都使用这些工具来改善其铸造过程。通过结合3D扫描,CAD,模拟和快速原型制作,团队可以减少孔隙率等缺陷并获得更好的表面质量。

图案处理和存储

正确处理和存储图案可防止损坏和失真。尤其是蜡模式,如果不小心处理,可能会变形。团队应调整释放剂并使用喷射销来减少死亡射出期间的损坏。以避免压力的方式存储模式有助于保持其形状。

| 区域 | 原因 | 推荐的最佳实践 |

|---|---|---|

| 蜡模式处理 | 弹出过程中的损坏 | 使用释放剂和喷射销 |

| 蜡模式存储 | 对存储不当的失真 | 存放以防止压力并保持形状 |

| 铸造处理 | 固化后的损坏 | 仔细处理,尤其是在热的时候 |

| 机械清洁 | 清洁过程中的损坏 | 降低速度或在爆破过程中使用橡胶块 |

| 运输 | 运输过程中的损坏 | 使用稳定的购物车和水平地板 |

笔记: 从图案创建到运输,将图案和铸件保持最佳状态,在每个阶段都要仔细处理。

霉菌准备和质量控制

模具制备和质量控制对投资快速原型制作项目的成功产生了巨大影响。图案的准确性和表面粗糙度为最终铸造质量奠定了基础。 SLA图案通常提供最佳的维度准确性和表面饰面,从而导致铸造率更高。

- 具有低灰分含量和稳定尺寸的新型轻型树脂有助于减少铸造缺陷。

- 后处理步骤,例如打蜡和抛光,改善了表面平滑度和外壳完整性。

- 质量控制检查尺寸稳定性和表面饰面可以将使用SLA图案制成的铸件以上的速率高于95%。

快速原型制定方法和仔细制备的选择会影响成本,输送时间和适应性。严格的质量控制在各个步骤有助于最大程度地减少缺陷并确保一致的结果。

提示: 将时间投入霉菌准备和质量检查。这项工作以更少的缺陷,更好的通过率和更顺畅的生产得到回报。

克服投资快速原型制作方面的挑战

管理模式失真和收缩

模式失真和收缩 可能会引起工程师的头痛。他们经常在打印或铸造后看到零件翘曲或更改尺寸。为了解决这个问题,团队使用沿X,Y和Z轴的补偿测试件。这些测试片有助于测量模式缩小或扭曲的程度。然后,工程师使用基于实际数据的比例因素调整CAD模型。他们还控制着构建方向,以减少卷发和塑造变化。许多铸造厂使用Taguchi方法(一种统计方法)来微调过程参数,例如激光功率和床温度。这种方法有助于保持零件的忠诚形状。

解决表面饰面问题

光滑的表面饰面在外观和功能上都具有很大的不同。糟糕的饰面可能会导致额外的工作,甚至会导致拒绝。团队经常使用后处理步骤,例如抛光或珠子爆破来提高表面质量。他们还优化了加工参数,并使工具保持最高形状。选择正确的图案材料并保持清洁模具进一步降低了粗糙度。当工程师及早发现表面缺陷时,他们可以在移至下一阶段之前修复它们。

确保尺寸准确性

维度精度对每个原型都很重要。铸造厂依靠CNC加工或3D打印制造的精确蜡图案,以使零件保持紧密的公差。他们控制蜡模制期间的注入压力,有时会使用结构后或固定来纠正小错误。在模具中涂上特殊涂料可防止氧化并保持表面清洁。使用与生产相同的门控和通风系统确保原型与最终部分相匹配。这种方法使团队可以在没有惊喜的情况下测试现实世界的性能。

最小化最终铸件中的缺陷

缺陷会破坏铸造项目。为了防止它们,工程师使用高级仿真软件来预测倒金属之前的空气口袋或收缩等问题。他们经常选择3D打印的模具,以获得更好的精度和更少的未对准。使用传感器实时监测有助于控制铸造过程中的温度和压力。团队还使用真空辅助铸造来删除被困的空气和热等静止压力,以关闭内部毛孔。定期进行质量检查,包括非破坏性测试,尽早发现问题。通过分析缺陷模式并调整过程,团队不断改善其结果。

最佳实践,以持续的结果进行投资快速原型制作

与经验丰富的合作伙伴合作

与经验丰富的合作伙伴合作为公司带来了真正的优势。这些合作伙伴带来了多年的专业知识和快速铸造原型的良好往绩。他们使用高级的3D打印和铸造技术,这可以帮助团队更快地获得更好的结果。他们的严格 质量控制 认证意味着每个原型都符合高标准。熟练的工程师早期发现缺陷,并提出改进,节省时间和金钱。良好的沟通使每个人都在同一页面上,使整个过程更加顺畅。团队还受益于适合其独特需求的个性化解决方案。通过与合适的提供商合作,公司看到了更高的精度,更少的错误和更快的市场途径。

持续的过程改进

行业领导者建议采用分步方法,以保持结果一致。这是一些最佳实践:

- 使用3D打印,例如立体光刻,以柔性且具有成本效益的蜡模式。

- 将预先设计的门控系统整合到蜡模式中,以实现稳定的金属流动。

- 用金属棒将图案连接到中央浇口上,以使其具有较强,易于处理的簇。

- 使用多轴机器人甚至浸入陶瓷浆中。

- 用几层陶瓷和难治性涂层来建立外壳。

- 用受控炉或蒸汽去除蜡以保护外壳。

- 高温烧结外壳,使其坚固并准备好金属倒入。

- 测试合金并在感应炉中准备熔体,以提高金属质量。

- 通过过滤器将金属倒入预热的模具中,以提高铸造完整性。

- 仔细去除陶瓷贝壳以使铸件保持良好的状态。

提示:自动化和仔细的过程控制有助于团队重复成功并避免常见错误。

利用反馈和数据

智能团队使用过去项目的反馈和数据,每次都会变得更好。他们在现实情况下测试原型,并尽早解决问题。审查旧项目可以帮助他们了解什么有效,什么无效。工程支持将反馈变成更好的设计和流程。质量控制数据显示了在哪里改进,而过去的交货时间和容量数则有助于计划未来的工作。

| 反馈/数据源 | 它如何帮助下一个项目 |

|---|---|

| 仿真结果 | 现场过程风险并控制关键因素 |

| 质量控制数据 | 尽早发现缺陷并提高质量 |

| 设计迭代结果 | 制作模具之前避免昂贵的错误 |

| 物质性能反馈 | 选择更好的图案材料和外壳方法 |

| 过程参数数据 | 微调脱水,倒入和完成步骤 |

从每个项目中学习的团队都会提高标准质量和效率。

应用权利 投资铸造快速原型制作 方法可以帮助团队实现更好的表面质量和准确性。专家建议轻巧的结构,空心零件和智能材料选择。通过遵循最佳实践和克服挑战,公司看到了越来越多的业绩,成本较低和较高质量的原型。

FAQ

投资快速原型制作的主要优势是什么?

投资铸造快速原型制作 让团队快速创建复杂的零件。他们可以快速测试设计并节省工具的资金。此方法适用于小批量生产。

您可以使用任何3D打印机用于投资铸造模式吗?

并非每个3D打印机都适用于此过程。团队需要使用蜡,SLA树脂或特殊塑料的打印机。这些材料在铸造过程中干净地燃烧。

如何改善铸造原型的表面饰面?

团队经常抛光或珠子炸毁铸件。他们还选择高分辨率模式材料。好的 霉菌准备 有助于创建光滑的表面。