والو حصوں کے لئے سٹینلیس سٹیل کی صحت سے متعلق کاسٹنگ پائیدار اور درست اجزاء تیار کرنے کے لئے سرمایہ کاری کاسٹنگ کا استعمال کریں۔ یہ طریقہ سخت رواداری اور پیچیدہ ڈیزائنوں کو حاصل کرتا ہے ، جو پیچیدہ والو جیومیٹریوں کے لئے ضروری ہیں۔ صنعتوں پر انحصار کرتا ہے سٹینلیس سٹیل کی سرمایہ کاری کاسٹنگ ان کی سنکنرن مزاحمت اور طاقت کے ل .۔ اجزاء جیسے والو باڈی اور ڈسکس ، خاص طور پر وہ جو بنائے گئے ہیں 304 سٹینلیس سٹیل کی سرمایہ کاری کاسٹنگ، کارکردگی سے سمجھوتہ کیے بغیر شدید حالات کا مقابلہ کرنے کی ان کی صلاحیت سے فائدہ اٹھائیں۔

What Are Stainless Steel Precision Castings?

Stainless steel precision castings are crafted using advanced techniques to achieve exceptional accuracy and quality. This process, often referred to as investment casting, is ideal for creating complex components like valve parts. Let’s explore how this process works, the properties of stainless steel, and the benefits it offers.

Investment Casting Process

Investment casting, also known as the lost-wax method, involves creating a wax model of the desired part. This model is coated with a ceramic shell, which hardens to form a mold. Once the wax is melted away, molten stainless steel is poured into the mold to create the final product. This method ensures high precision and intricate detailing.

Key metrics highlight the efficiency of this process:

- Dimensional tolerances can reach ±0.005 inches.

- Surface finishes are as smooth as Ra 125 microinches.

- Material utilization rates can go up to 98%.

These features make investment casting a preferred choice for industries requiring precision and minimal material waste.

Properties of Stainless Steel

Stainless steel’s unique properties make it an excellent material for precision castings. It offers high tensile strength (500–750 MPa) and yield strength (500–650 MPa), ensuring durability. Its corrosion resistance varies by grade but is generally excellent, making it suitable for harsh environments. Additionally, stainless steel withstands extreme temperatures, from -200 °C to 2,000 °C, depending on the grade.

| جائیداد | Value/Notes |

|---|---|

| Density | 7.75 x 10³ to 8.05 x 10³ kg/m³ |

| تناؤ کی طاقت | 500–750 MPa |

| سنکنرن مزاحمت | High to very high, depending on the grade |

| Heat Resistance | Up to 2,000 °C for certain grades |

These characteristics ensure that stainless steel precision castings for valve parts perform reliably under demanding conditions.

Benefits of Precision Casting

Precision casting offers several advantages over traditional methods. It delivers superior dimensional accuracy, excellent surface quality, and enhanced material strength. These benefits make it ideal for industries like aerospace and automotive manufacturing, where precision is critical.

| Characteristic | سٹینلیس سٹیل کی صحت سے متعلق معدنیات سے متعلق | Traditional Casting Methods |

|---|---|---|

| جہتی درستگی | High due to advanced processes like silica sol shell | Generally lower accuracy |

| سطح کا معیار | Excellent, enhanced by precision casting techniques | Average surface quality |

| درخواست کے علاقے | High-precision industries (e.g., aerospace) | Broader applications, less precision |

By combining the strengths of stainless steel with the precision of investment casting, manufacturers can produce durable and reliable valve components.

Why Use Stainless Steel Precision Castings for Valve Parts?

سنکنرن مزاحمت

سٹینلیس سٹیل کی صحت سے متعلق کاسٹنگ for valve parts excel in environments where corrosion is a concern. Stainless steel’s natural resistance to rust and chemical damage makes it ideal for industries like food processing, marine, and chemical manufacturing. This material forms a protective oxide layer on its surface, which prevents corrosion even in harsh conditions.

For example, components like valve bodies and discs made from stainless steel can withstand exposure to moisture, salt, and chemicals without degrading. This durability reduces the need for frequent replacements, saving time and money in the long run.

| خصوصیت | تفصیل |

|---|---|

| سنکنرن مزاحمت | Stainless steel is highly resistant to rust and chemical damage, making it perfect for harsh environments. |

جہتی درستگی

Precision matters when manufacturing valve parts. Stainless steel precision castings achieve exceptional جہتی درستگی, ensuring components fit perfectly and function as intended. Advanced techniques, such as robotic molding systems and real-time monitoring, help maintain tight tolerances during production.

This accuracy is critical for industries that rely on valves to regulate flow, pressure, or temperature. Adherence to standards like ASTM ensures that every casting meets strict quality requirements. By using this method, manufacturers can produce intricate designs with consistent results.

- Dimensional accuracy ensures components meet exact specifications.

- Techniques like controlled cooling and uniform mold creation enhance precision.

- Standards such as ASTM A995 guarantee quality and reliability.

طاقت اور استحکام

Valve parts endure significant stress during operation. Stainless steel precision castings provide the strength and durability needed to handle these demands. With high tensile and yield strength, these components resist wear, impact, and fatigue over time.

For instance, stainless steel castings are often used in severe service applications, such as high-pressure systems or extreme temperatures. Their ability to maintain structural integrity under such conditions makes them a reliable choice for critical industries.

| Property Type | تفصیل |

|---|---|

| Tensile Properties | Includes tensile strength, yield strength, elongation, and reduction of area. |

| Impact Properties | Determined by energy absorbed during fracture in a Charpy V-notch impact test. |

| Fatigue Properties | Indicates stress versus number of cycles, with an endurance limit for steel. |

Stainless steel precision castings for valve parts combine corrosion resistance, dimensional accuracy, and durability, making them indispensable for industries requiring reliable and long-lasting components.

Applications of Stainless Steel Precision Castings for Valve Parts

Common Valve Components

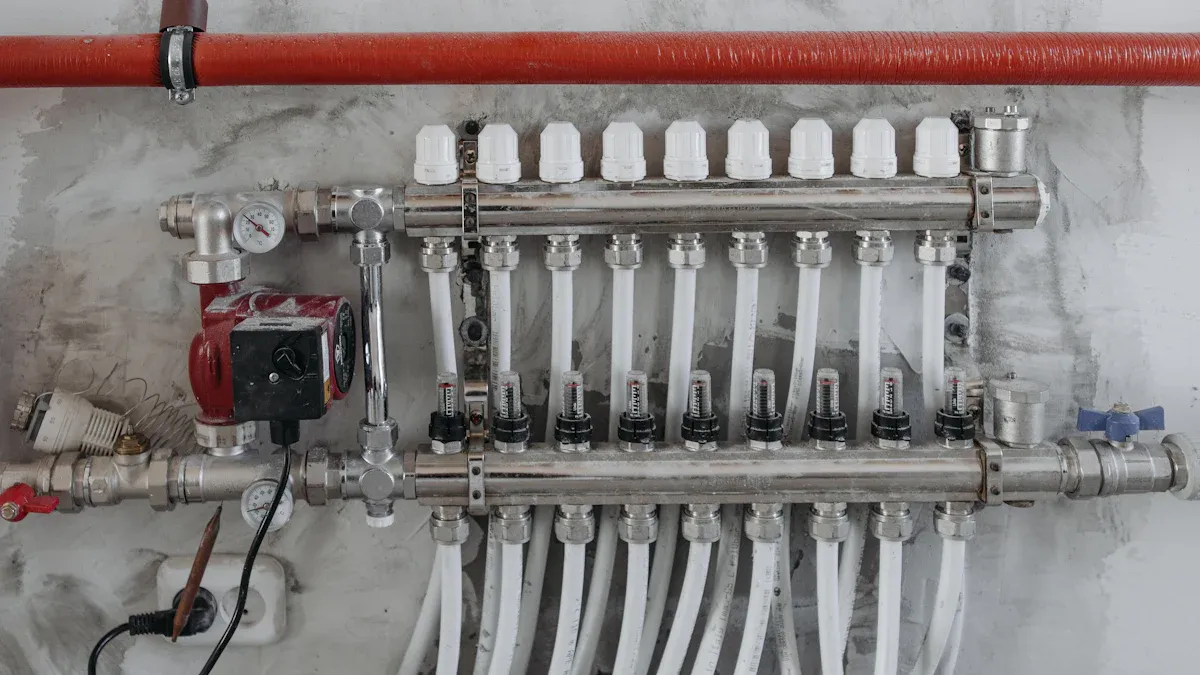

سٹینلیس سٹیل کی صحت سے متعلق کاسٹنگ play a vital role in manufacturing various valve components. These castings are ideal for creating intricate shapes and designs that are essential for valve functionality. Common components include valve bodies, discs, bonnets, and glands. Each part benefits from the precision and durability offered by stainless steel.

| Component Type | Manufacturing Method | Material Used |

|---|---|---|

| Impellers | سرمایہ کاری کاسٹنگ | سٹینلیس سٹیل |

| Intricate Valve Bodies | سرمایہ کاری کاسٹنگ | سٹینلیس سٹیل |

| Delicate Internal Passages | سرمایہ کاری کاسٹنگ | سٹینلیس سٹیل |

These components ensure valves operate efficiently, even in challenging environments. The ability to produce complex shapes makes stainless steel precision castings a preferred choice for valve manufacturers.

Industrial Applications

Industries rely heavily on stainless steel precision castings for valve parts due to their versatility and performance. These castings are widely used in sectors like aerospace, automotive, and medical. For example:

- ایرو اسپیس: Stainless steel castings are used in aircraft engine parts, where strength and heat resistance are critical.

- آٹوموٹو: Exhaust systems and other components benefit from the durability of stainless steel.

- Medical Devices: Surgical instruments and implants require biocompatible and corrosion-resistant materials.

Additionally, industrial machinery, pumps, and heat exchangers frequently incorporate stainless steel castings. The high demand for these materials stems from their ability to withstand extreme conditions while maintaining reliability.

Role in High-Performance Valves

High-performance valves demand materials that can endure harsh environments. Stainless steel precision castings meet these requirements by offering exceptional durability and resistance to corrosion, heat, and stress. Components made from stainless steel perform reliably in applications involving high pressure or extreme temperatures.

- Stainless steel castings extend the lifespan of valve components.

- They maintain performance under abusive working conditions.

- Proper material selection ensures the castings meet specific operational demands.

These qualities make stainless steel precision castings indispensable for industries requiring high-performance valves, such as chemical processing and power generation.

Comparison with Other Casting Methods

ریت کاسٹنگ

Sand casting is one of the oldest and most cost-effective casting methods. It uses sand molds to shape molten metal into the desired form. This method works well for simpler designs and larger components. However, it lacks the precision and surface quality offered by stainless steel precision casting. Sand casting often requires additional machining to achieve the desired finish, which can increase production time and costs.

Key differences include:

- لاگت: Sand casting is cheaper upfront but may involve higher post-processing expenses.

- درستگی: Dimensional tolerances are less precise compared to precision casting.

- درخواستیں: Commonly used in general manufacturing for non-critical parts.

While sand casting is economical, it doesn’t match the durability and precision of stainless steel precision castings for valve parts.

ڈائی کاسٹنگ

Die casting involves forcing molten metal into a mold cavity under high pressure. This method is ideal for medium-complexity parts and offers good dimensional accuracy. It’s widely used in the automotive industry for components like engine blocks and transmission cases. However, die casting struggles with intricate designs and high-strength requirements.

Advantages of die casting include:

- Efficiency: High production rates make it suitable for mass production.

- سطح ختم: Produces smoother surfaces than sand casting.

- حدود: Not suitable for high-temperature alloys like stainless steel.

Die casting provides cost-effective solutions for medium-complexity parts but falls short in producing the intricate shapes and superior finishes achieved by precision casting.

Centrifugal Casting

Centrifugal casting uses rotational force to distribute molten metal within a mold. This process minimizes defects and creates components with uniform density. It’s particularly effective for large, cylindrical parts like pipes and rings. However, it faces challenges with complex shapes and smaller components.

Key benefits include:

- طاقت: Produces high-strength parts with minimal defects.

- مادی کارکردگی: Reduces waste and machining costs.

- حدود: Restricted to specific shapes and sizes.

Centrifugal casting excels in producing durable, large-scale components but lacks the versatility and precision of stainless steel precision castings for valve parts.

| معدنیات سے متعلق طریقہ | فوائد | درخواستیں |

|---|---|---|

| سٹینلیس سٹیل کی صحت سے متعلق معدنیات سے متعلق | High dimensional accuracy, excellent surface quality, higher added value | Aerospace, national defense |

| ریت کاسٹنگ | Lower cost, suitable for simpler designs | General manufacturing |

| Low-Pressure Die Casting | Cost-effective for medium complexity parts | Automotive, general applications |

| Centrifugal Casting | Suitable for large parts, high strength | Heavy machinery, industrial components |

Each casting method has its strengths, but stainless steel precision casting stands out for its ability to produce intricate designs with exceptional accuracy and durability.

Stainless steel precision castings for valve parts offer unmatched precision, strength, and corrosion resistance. With tolerances as tight as ±0.1mm and exceptional durability, they meet the demands of industries like aerospace and automotive. Their ability to produce reliable, high-quality components makes them indispensable for applications requiring exacting standards and long-lasting performance.

The growing need for durable valve components in infrastructure and industrial sectors highlights the importance of these castings. Their superior surface finish and dimensional accuracy reduce machining needs, saving time and resources.

سوالات

What makes stainless steel precision castings better than other materials for valve parts?

Stainless steel offers unmatched corrosion resistance, strength, and durability. These qualities make it ideal for valve parts used in harsh environments or high-pressure applications.

Can stainless steel precision castings handle extreme temperatures?

Yes! Stainless steel precision castings can withstand temperatures ranging from -200 °C to 2,000 °C, depending on the grade. This makes them suitable for demanding industrial uses.

Are stainless steel precision castings cost-effective?

Absolutely. While the initial cost may be higher, their durability and low maintenance reduce long-term expenses. They also minimize material waste during production, saving resources.